Tsananguro yeChigadzirwa

Ruzivo Rwakajairika - ASME/ANSI B16.5 & B16.47 - Mapaipi eFlanges neFlanged Fittings

Muyero weASME B16.5 unosanganisira zvinhu zvakasiyana-siyana zvemaflange emapaipi neflange dzakaiswa, kusanganisira kuyera kwekupisa kwemhepo, zvinhu, saizi, kushivirira, kumaka, kuyedza, uye kuratidza nzvimbo dzinovhurika dzezvikamu izvi. Muyero uyu unosanganisira maflange ane mazita ekirasi yerating anotangira pa150 kusvika 2500, achifukidza saizi kubva kuNPS 1/2 kusvika kuNPS 24. Unopa zvinodiwa muzvikamu zvemetric neUS. Zvakakosha kuziva kuti muyero uyu unongogumira kumaflange neflange dzakaiswa nezvinhu zvakagadzirwa necast kana forged, kusanganisira mablind flanges uye maflanges chaiwo akagadzirwa nezvinhu zvakagadzirwa necast, forged, kana plate.

Kune mapaipi ekuisa flanges ne flanges fittings akakura kupfuura 24" NPS, ASME/ANSI B16.47 inofanira kutariswa.

Mhando Dzakajairika dzeFlange

● MaFlanges Anotsvedza: MaFlanges aya anowanzo chengetwa muANSI Class 150, 300, 600, 1500 & 2500 kusvika 24" NPS. Anotsvedzwa pamusoro pepombi kana magumo ekubatanidza uye anosungirirwa panzvimbo yawo, zvichibvumira mafillet welds mukati nekunze kweflange. Mavhezheni ekuderedza anoshandiswa kuderedza saizi yemitsara kana nzvimbo iri shoma.

● Maflange emutsipa weWeld: Maflange aya ane hub refu uye ukobvu hwakatsetseka, zvichiita kuti weld ipinde zvakakwana papombi kana painopinda. Anoshandiswa mumamiriro ezvinhu akaomarara ekushanda.

● Maflange eMapazi: Akabatanidzwa nemagumo estub, maflange emapazi anotsvedzwa pamusoro pemafitting estub end uye anobatanidzwa nekusveta kana dzimwe nzira. Dhizaini yavo yakasununguka inobvumira kurongeka kuri nyore panguva yekubatanidza nekuputsa.

● Mafurangi Ekutsigira: Mafurangi aya haana kukwidziridzwa uye anoshandiswa nemhete dzekutsigira, zvichipa mhinduro dzinodhura dzekubatanidza maflangi.

● Maflange Akarukwa (Akakwenenzverwa): Akaneta kuti aenderane nepaipi chaiyo iri mukati medhayamita, maflange akarukwa anogadzirwa nepaipi yakarukwa kudivi rekumashure, kunyanya pamapaipi madiki.

● Maflange eSocket Weld: Akafanana nemaflange eslip-on, maflange esocket weld anogadzirwa kuti aenderane nemasocket ehukuru hwepombi, zvichibvumira fillet welding kurutivi rwekumashure kuchengetedza kubatana. Anowanzo shandiswa kumapombi madiki.

● Maflanges Akapofumara: Maflanges aya haana buri repakati uye anoshandiswa kuvhara kana kuvharira magumo ehurongwa hwemapaipi.

Idzi ndidzo dzimwe dzemhando dzemaflange emapaipi anoshandiswa mumaindasitiri akasiyana-siyana uye mumabhizinesi. Sarudzo yerudzi rweflange inoenderana nezvinhu zvakaita sekumanikidzwa, tembiricha, uye rudzi rwemvura iri kutakurwa, pamwe nezvinodiwa papurojekiti chaiyo. Kusarudzwa nekuiswa kwemaflange kwakakodzera kwakakosha pakushanda kwakachengeteka uye nemazvo kwemasisitimu emapaipi.

Magadzirirwo

| ASME B16.5: Simbi yeKabhoni, Simbi Isina Chinotenderera, Simbi yeAlloy |

| EN 1092-1: Simbi yeKabhoni, Simbi Isina Chinotenderera, Simbi yeAlloy |

| DIN 2501: Simbi yeKabhoni, Simbi Isina Chinotenderera, Simbi yeAlloy |

| GOST 33259: Simbi yeKabhoni, Simbi Isina Chinotenderera, Simbi yeAlloy |

| SABS 1123: Simbi yeKabhoni, Simbi Isina Chinotenderera, Simbi yeAlloy |

Zvinhu zveFlange

Maflanges anosungirirwa papombi nepaburi remidziyo. Saka, inogadzirwa nezvinhu zvinotevera;

● Simbi yekabhoni

● Simbi isina alloy yakawanda

● Simbi isina ngura

● Musanganiswa wezvinhu zvekunze (Stub) nezvimwe zvinhu zvinotsigira

Rondedzero yezvinhu zvinoshandiswa mukugadzira inotaurwa muASME B16.5 & B16.47.

● ASME B16.5 -Mapaipi eFlanges neFlanged Fittings NPS ½” kusvika 24”

● ASME B16.47 -Mafurangi esimbi ane dhayamita hombe NPS 26” kusvika 60”

Zvinowanzoshandiswa kugadzira zvinhu zvakagadzirwa

● Simbi yeKabhoni: – ASTM A105, ASTM A350 LF1/2, ASTM A181

● Simbi yeAlloy: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

● Simbi Isina Zvisimbiso: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Kirasi 150 Slip-on Flange Dimensions

| Saizi mu Inch | Saizi mu mm | Dia rekunze. | Gobvu reFlange. | Hub OD | Kureba kweFlange | RF Dia. | Kureba kweRF | PCD | Chibooreso cheSocket | Nhamba yeMabhoti | Saizi yeBhoti UNC | Kureba kweBhodhi reMuchina | Kureba kweRF Stud | Saizi yeHole | Saizi yeISO Stud | Kurema mu kg |

|

|

| A | B | C | D | E | F | G | H |

|

|

|

|

|

|

|

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Kirasi 150 Weld Neck Flange Dimensions

| Saizi mu Inch | Saizi mu mm | Dhayamita yekunze | Ukobvu hweFlange | Hub OD | Weld Neck OD | Kureba Kwemutsipa Wekushongedza | Bore | Dhayamita yeRF | Kureba kweRF | PCD | Chiso chakasungirirwa |

|

|

| A | B | C | D | E | F | G | H | I | J |

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Chibooreso chemutsipa chekuwedera chinobva pachirongwa chepombi | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Kirasi 150 Bofu Flange Dimensions

| Saizi | Saizi | Kunze | Flange | RF | RF | PCD | Nhamba ye | Saizi yeBhodhi | Bhodhi remuchina | RF Mudziyo | Saizi yeHole | ISO Stud | Huremu |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

Standard & Giredhi

| ASME B16.5: Mapaipi eFlanges neFlanged Fittings | Zvishandiso: Simbi yeCarbon, Simbi Isina Stainless, Simbi yeAlloy |

| EN 1092-1: Maflanges nemajoini azvo - Maflanges akatenderera emapaipi, mavharuvhu, zvigadziko, uye zvishongedzo, PN Yakasarudzwa - Chikamu 1: Maflanges esimbi | Zvishandiso: Simbi yeCarbon, Simbi Isina Stainless, Simbi yeAlloy

|

| DIN 2501: Mafurangi uye Majoini Akakombama | Zvishandiso: Simbi yeCarbon, Simbi Isina Stainless, Simbi yeAlloy |

| GOST 33259: Maflange eMavharuvhu, Zvigadziko, uye Mapaipi ekumanikidza kuPN 250 | Zvishandiso: Simbi yeCarbon, Simbi Isina Stainless, Simbi yeAlloy |

| SABS 1123: Maflange eMapaipi, Mavharuvhu, uye Zvishandiso | Zvishandiso: Simbi yeCarbon, Simbi Isina Stainless, Simbi yeAlloy |

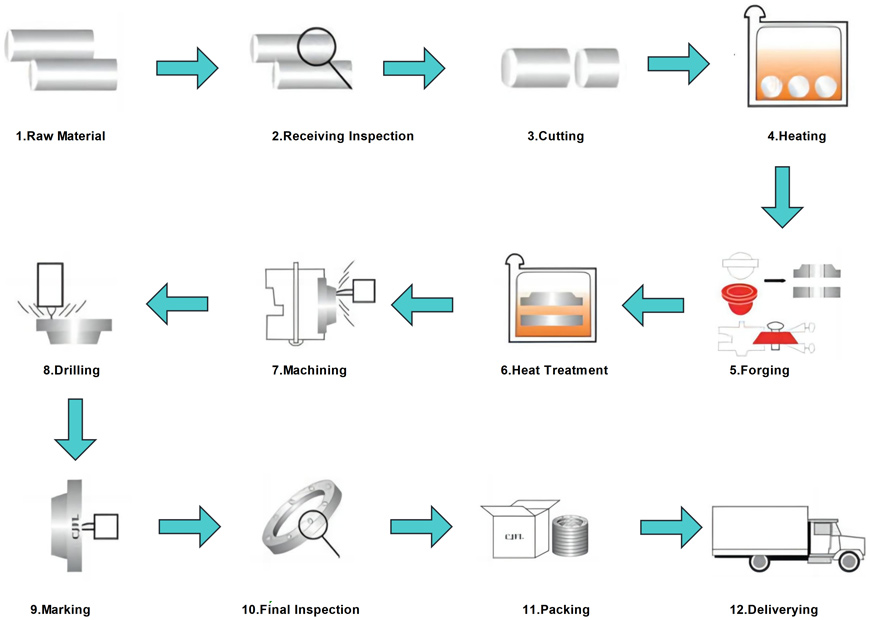

Maitiro Ekugadzira

Kudzora Hunhu

Kuongorora Zvinhu Zvisina Kugadzirwa, Kuongorora Makemikari, Kuedza Kwemuchina, Kuongorora Zvinoonekwa, Kuongorora Dimension, Kuedza Kukombama, Kuedza Kutsvedza, Kuedza Kwekukanganisa, Kuedza DWT, Kuongorora Kusingaparadze (UT, MT, PT, X-Ray,), Kuedza Kuoma, Kuedza Kudzvanywa, Kuedza Kubuda Kwezvigaro, Kuedza Metallography, Kuedza Kuora, Kuedza Kuramba Moto, Kuedza Kupfapfaidza Munyu, Kuedza Kushanda Kwemvura, Kuedza Torque neThrust, Kuongorora Kupenda Nekuputira, Ongororo Yemagwaro…..

Kushandisa & Kushandiswa

Maflanges zvikamu zvakakosha zvemaindasitiri zvinoshandiswa kubatanidza mapombi, mavharuvhu, michina nezvimwe zvikamu zvemapaipi. Anoita basa guru mukubatanidza, kutsigira uye kusimbisa masisitimu emapaipi. Maflanges anoshanda sezvikamu zvakakosha mumashandisirwo akasiyana-siyana emaindasitiri, anosanganisira:

● Masisitimu eMapombi

● Mavharuvhu

● Midziyo

● Kubatana

● Kuvhara

● Kutarisira Kumanikidzwa

Kurongedza & Kutumira

KuWomic Steel, tinonzwisisa kukosha kwekurongedza kwakachengeteka uye kutumira kwakavimbika kana zvasvika pakuendesa mapipe fittings edu emhando yepamusoro pamusuwo wako. Heino pfupiso yemaitiro edu ekurongedza nekutumira kuti uwane ruzivo rwako:

Kurongedza:

Mapaipi edu emagetsi akanyatsorongedzwa kuitira kuti ave nechokwadi chekuti anosvika kwauri ari mumamiriro akanaka, akagadzirira zvaunoda mumaindasitiri kana mumabhizinesi. Maitiro edu ekurongedza anosanganisira matanho anotevera akakosha:

● Kuongororwa Kwemhando: Maflange ese asati aiswa, anoongororwa zvakakwana kuti ave nechokwadi chekuti anosangana nezvinodiwa zvedu zvakasimba zvekushanda uye kuvimbika.

● Kuvhara Kunodzivirira: Zvichienderana nerudzi rwezvinhu uye mashandisirwo azvo, maflange edu anogona kugamuchira kufukidza kunodzivirira kudzivirira ngura nekukuvadzwa panguva yekufambisa.

● Kusunga Zvakachengeteka: Maflange anosungirirwa pamwe chete zvakachengeteka, zvichiita kuti arambe akasimba uye akachengetedzwa panguva yese yekutumira.

● Kunyora uye Kunyora Magwaro: Pakeji yega yega yakanyorwa zvakajeka neruzivo rwakakosha, kusanganisira zvirevo zvechigadzirwa, huwandu, uye chero mirairo yakakosha yekubata. Magwaro akakodzera, akadai sezvitupa zvekutevedzera mitemo, anowanikwawo.

● Kurongedza Kwakagadzirwa Nemunhu: Tinogona kugamuchira zvikumbiro zvekurongedza zvakasarudzika zvichienderana nezvaunoda, tichiona kuti maflange ako akagadzirwa sezvaanoda.

Kutumira:

Tinoshanda pamwe chete nevatinoshanda navo mukutakura zvinhu kuti tive nechokwadi chekuti zvinhu zvinotumirwa zvakanaka uye nenguva. Chikwata chedu chekutakura zvinhu chinogadzirisa nzira dzekutakura zvinhu kuti zvideredze nguva dzekutakura zvinhu uye kuderedza njodzi yekunonoka. Pakutumira zvinhu kunze kwenyika, tinoshandisa magwaro ese anodiwa ekutumira zvinhu uye kutevedzera mitemo yemutero kuti zvive nyore kubvisa zvinhu mutero. Tinopa nzira dzekutumira zvinhu dzinochinjika, kusanganisira kutumira zvinhu nekukurumidza kana paine zvinodiwa nekukurumidza.