Nhanganyaya:

API 5L imhando yakajairwa yakagadzwa neAmerican Petroleum Institute (API) yemapombi esimbi asina musono uye akasungirirwa anoshandiswa mukutakura zvinhu mukati memaindasitiri epetroleum negasi rechisikigo. Womic Steel, kambani inotungamira mukugadzira mapaipi emuchina weAPI 5L, inopa mhando dzakasiyana dzezvigadzirwa zvinosangana nemamaki akasiyana uye zvakatsanangurwa. Chinyorwa chino chinopa kuenzanisa kwakadzama kwemakemikari, hunhu hwemakanika, uye mwero wekuyedza wemagiredhi akasiyana eAPI 5L, ese ari maviri PSL1 nePSL2 mumhando nhatu dzemapaipi: ERW (Electric Resistance Welded), LSAW (Longitudinal Submerged Arc Welded), uye SMLS (Seamless).

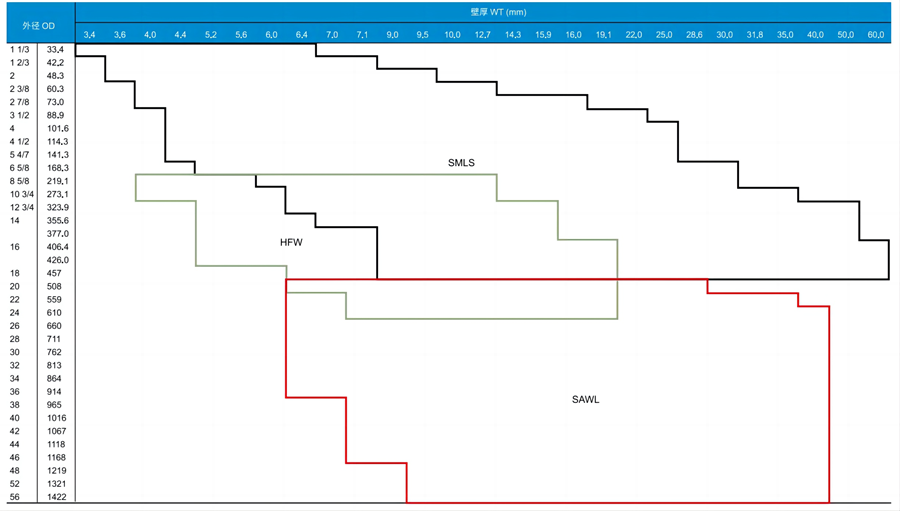

Kugona Kugadzira uye Range:

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Minimum mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| SMLS | B | X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Kushivirira kwedhayamita yekunze

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| API Spec SO 3183 | D<60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm≤D≤168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3mm | +0.5%/-0.5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0.75%/-0.75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0.5%/-0.5% | ± 2.0mm | ±1.6mm | ≤1.5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Cherechedza: D ndiyo dhayamita yekunze yepombi.

Kushivirira Ukobvu hweMadziro

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| API Spec ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12.5% | ||

| - | 5.0mm | +10%/-10% | ||

| - | 15.0mmst<25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm≤t<30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t<37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

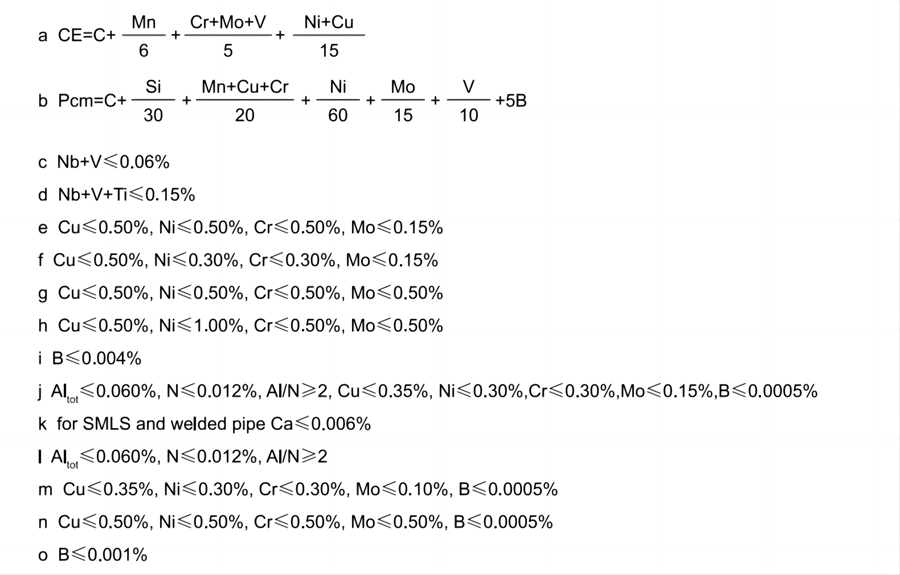

Kuongorora Makemikari

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | Pcm | 备注 |

| zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | |||||

| API Spec 5L | 无缝管 | PSL1 | L210 kana A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 kana B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c,d,e,o | |||

| L290 kana X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L320 kana X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 kana X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 kana X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 kana X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 kana X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L485 kana X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | L245N kana BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | c,f,o | ||

| L290N kana X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N kana X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N kana X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N kana X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N kana X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Sezvakabvumiranwa | d,g,o | ||||

| L245Q kana BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L290Q kana X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q kanaX46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 kana ×52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L390Q kana X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415Q kana X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450Q kana X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485Q kana X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555Q kana X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Sezvakabvumiranwa | Mhoro | ||||

| 酸性服 | L245NS kana BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c,d,j,k | ||

| L290NS kana X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| L320NS kana X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | dj,k | |||

| L360NS kana X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| L245QS kana BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L290QS kana X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L320QS kana X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| L360QS kana X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| L390QS kana X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| L415QS kana X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | dj,k | |||

| L450QS kana X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| L485QS kana X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | CEa | Pcm | 备注 |

| zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | |||||

| AP|SPEC 5L | 无缝管 | 海上服 | L245NO kana BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c,d,Ini,m |

| L290NO kana X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO kana X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d,Ini,m | |||

| L360NO kana X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,Ini | |||

| L245QO kana BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L290QO kana X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L320QO kana X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| L360QO kana X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,I,n | |||

| L390QO kana X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,I,n | |||

| L415QO kana X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,I,n | |||

| L455QO kana X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,I,n | |||

| L485Q0 kana X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| L555QO kana X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Sezvakabvumiranwa | d,I,n | ||||

| 焊管 | PSL1 | L245 kana B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 kanaX42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 kanaX46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 kana X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 kanaX56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 kanaX60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 kana X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 kana X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | 1245M kana BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| L290M kana X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320M kana X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L360M kana X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L390M kana X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M kana X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450M kana X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485M kana X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555M kana X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CEa | Pcm | 备注 |

| zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | zvakanyanya | |||||

| API Spec 5L | 焊管 | 酸性服 | L245MS kana BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| L290MS kana X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| L320MS kana X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| L360MS kana X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| L390MS kana X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| L415MS kana X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| L450MS kana X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| L485MS kana X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | dj,k | |||

| 海上服 | L245MO kana BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| L290MO kana X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| L320MO kana X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Ini, m | |||

| L360MO kana X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,I,n | |||

| L390MO kana X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO kana X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,I,n | |||

| L450MO kana X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,I,n | |||

| L485MO kana X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| L555MO kana X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,I,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API Spec 5L | PSL1 | L210 kana A | Minimum | 210 | 335 | a |

| 335 |

| L245 kana B | Minimum | 245 | 415 | a |

| 415 | ||

| L290 kana X42 | Minimum | 290 | 415 | a |

| 415 | ||

| L320 kana X46 | Minimum | 320 | 435 | a |

| 435 | ||

| L360 kana X52 | Minimum | 360 | 460 | a |

| 460 | ||

| L390 kana X56 | Minimum | 390 | 490 | a |

| 490 | ||

| L415 kana X60 | Minimum | 415 | 520 | a |

| 520 | ||

| L450 kana X65 | Minimum | 450 | 535 | a |

| 535 | ||

| L485 kana X70 | Minimum | 485 | 570 | a |

| 570 | ||

| PSL2 | L245N kana BN | Minimum | 245 | 415 | a |

| 415 | |

| Max | 450 | 655 |

| 0.93 |

| |||

| L290N kana X42N | Minimum | 290 | 415 | a |

| 415 | ||

| Max | 495 | 655 |

| 0.93 |

| |||

| L320N kana X46N | Minimum | 320 | 435 | a |

| 435 | ||

| Max | 525 | 655 |

| 0.93 |

| |||

| L360N kana X52N | Minimum | 360 | 460 | a |

| 460 | ||

| Max | 530 | 760 |

| 0.93 |

| |||

| L390N kana X56N | Minimum | 390 | 490 | a |

| 490 | ||

| Max | 545 | 760 |

| 0.93 |

| |||

| L415N kana X60N | Minimum | 415 | 520 | a |

| 520 | ||

| Max | 565 | 760 |

| 0.93 |

| |||

| L450Q kana X65Q | Minimum | 450 | 535 | a |

| 535 | ||

| Max | 600 | 760 |

| 0.93 |

| |||

| L485Q kana X70Q | Minimum | 485 | 570 | a |

| 570 | ||

| Max | 635 | 760 |

| 0.93 |

| |||

| L555Q kana X80Q | Minimum | 555 | 625 | a |

| 625 | ||

| Max | 705 | 825 |

| 0.93 |

| |||

| L625M kana X90M | Minimum | 625 | 695 | a |

| 695 | ||

| Max | 775 | 915 |

| 0.95 |

| |||

| L690M kana X100M | Minimum | 690 | 760 | a |

| 760 | ||

| Max | 840 | 990 |

| 0.97 |

| |||

| L830M kana X120M | Minimum | 830 | 915 | a |

| 915 | ||

| Max | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API Spec 5L | 酸性服 | L245NS kana BNS | Minimum | 245 | 415 | a |

| 415 |

| Max | 450 | 655 |

| 0.93 |

| |||

| L290NS kana X42NS | Minimum | 290 | 415 | a |

| 415 | ||

| Max | 495 | 655 |

| 0.93 |

| |||

| L320NS kana X46NS | Minimum | 320 | 435 | a |

| 435 | ||

| Max | 525 | 655 |

| 0.93 |

| |||

| L360NS kana X52NS | Minimum | 360 | 460 | a |

| 460 | ||

| Max | 530 | 760 |

| 0.93 |

| |||

| L390QS kana X56QS | Minimum | 390 | 490 | a |

| 490 | ||

| Max | 545 | 760 |

| 0.93 |

| |||

| L415QS kana X60QS | Minimum | 415 | 520 | a |

| 520 | ||

| Max | 565 | 760 |

| 0.93 |

| |||

| L450QS kana X65QS | Minimum | 450 | 535 | a |

| 535 | ||

| Max | 600 | 760 |

| 0.93 |

| |||

| L485QS kana X70QS | Minimum | 485 | 570 | a |

| 570 | ||

| Max | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO kana BNO | Minimum | 245 | 415 | a | - | 415 | |

| Max | 450 | 655 |

| 0.93 |

| |||

| L290NO kana X42NO | Minimum | 290 | 415 | a |

| 415 | ||

| Max | 495 | 655 |

| 0.93 |

| |||

| L320NO kana X46NO | Minimum | 320 | 435 | a |

| 435 | ||

| Max | 520 | 655 |

| 0.93 |

| |||

| L360NO kana X52NO | Minimum | 360 | 460 | a |

| 460 | ||

| Max | 525 | 760 |

| 0.93 |

| |||

| L390QO kana X56QO | Minimum | 390 | 490 | a |

| 490 | ||

| Max | 540 | 760 |

| 0.93 |

| |||

| L415QO kana X60QO | Minimum | 415 | 520 | a | - | 520 | ||

| Max | 565 | 760 |

| 0.93 |

| |||

| L450QO kana X65QO | Minimum | 450 | 535 | a | - | 535 | ||

| Max | 570 | 760 |

| 0.93 |

| |||

| L485Q0 kana X70Q0 | Minimum | 485 | 570 | a |

| 570 | ||

| Max | 605 | 760 |

| 0.93 |

| |||

| L555QO kana X80QO | Minimum | 555 | 625 | a |

| 625 | ||

| Max | 675 | 825 |

| 0.93 |

Cherechedza: a: Kureba kushoma uchishandisa equation inotevera: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | D<1422mm | D=1422mm | |

| ≤L415 kana X60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| >L415 kana X60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L450 kana X65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L485 kana X70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

Cherechedza: (1) Hunhu huri patafura hwakakodzera sampuli yakazara.

(2) Kukosha kuri mukati mebhuraketi ndiko kukosha kushoma kwechimwe chete, bhuraketi rekunze ndiko kukosha kweavhareji.

(3) Tembiricha yekuyedza: 0°C.

Mitemo Yekuyedza:

Mapaipi emhando yeAPI 5L akagadzirwa neWomic Steel ari kuyedzwa zvakasimba kuti ave nechokwadi chekuti anosangana nezvinodiwa zvepamusoro-soro. Mitemo yekuyedza inosanganisira:

Kuongorora Makemikari:

Kuumbwa kwemakemikari esimbi kunoongororwa kuti zvionekwe kuti inosangana nezvinodiwa zveAPI 5L specification.

Kuongororwa kwemakemikari kunoitwa uchishandisa spectrometer yekuverenga zvakananga kuti uone nemazvo kuumbwa kwezvinhu zvesimbi.

Kuedzwa kweMichina:

Hunhu hwemakanika hwakadai sekusimba kwesimba, simba rekudhonza, uye kureba zvinoedzwa kuona kuti zvinosangana nezvinodiwa zvakatarwa.

Kuyedzwa kwemuchina kunoitwa uchishandisa muchina wekuyedza tensile we60-ton kuyera simba uye ductility yesimbi.

Kuedzwa kweHydrostatic:

Kuongororwa kwemvura kunoitwa kuti pave nechokwadi chekuti pombi yacho yakasimba uye kuti inogona kumira kumanikidzwa kwainofanira kushandiswa.

Mapaipi anozadzwa nemvura uye anomanikidzwa, nguva yekuedzwa uye mwero wekumanikidzwa zvakatsanangurwa nemaitiro eAPI 5L.

Kuedzwa Kusingaparadze (NDT):

Nzira dzeNDT dzakadai sekuongorora kwe ultrasonic (UT) uye magnetic particle testing (MT) dzinoshandiswa kuona chero zvikanganiso kana kusagadzikana mupombi.

UT inoshandiswa kuona zvikanganiso zvemukati, ukuwo MT inoshandiswa kuona zvikanganiso zvepadenga.

Kuedzwa kweMhedzisiro:

Kuyedzwa kwesimba kunoitwa kuti kuone kusimba kwesimbi pakupisa kwakaderera.

Chiyedzo cheCharpy impact test chinowanzo shandiswa kuyera simba re impact rinotorwa nesimbi.

Kuedzwa kweKuoma:

Kuongororwa kwekuomarara kunoitwa kuti kuongororwe kuomarara kwesimbi, izvo zvinogona kuratidza simba rayo uye kukodzera kwayo kushandiswa kwakanangana.

Chiyedzo chekuomarara cheRockwell chinowanzo shandiswa kuyera kuomarara kwesimbi.

Kuongorora Zvimiro Zvidiki:

Kuongororwa kwechimiro chidiki kunoitwa kuti kuonekwe chimiro chezviyo uye mhando yese yesimbi.

Maikorosikopu yesimbi inoshandiswa kuongorora chimiro chesimbi uye kuona chero kusarongeka.

Nekutevedzera mitemo iyi yakaoma yekuyedza, Womic Steel inoita kuti mapaipi ayo eAPI 5L line asvike pazvinodiwa zvepamusoro-soro uye anopa mashandiro akavimbika mumashandisirwo akasiyana-siyana emaindasitiri.

Maitiro Ekugadzira:

1. Mapaipi eSimbi Asina Musono:

- Kusarudzwa Kwezvinhu Zvisina Kugadzirwa: Zvishandiso zvesimbi zvakatenderera zvemhando yepamusoro zvinosarudzwa kuti zvigadzirwe mapaipi esimbi asina musono.

- Kudziisa uye Kuboora: Mabheti acho anodziiswa kusvika pakupisa kwakanyanya uye obva aboorwa kuti pave negoko risina chinhu.

- Kutenderedza neSaizi: Goko rakaboorwa rinozotenderedzwa uye kutatamurwa kusvika padhayamita neukobvu hwaunoda.

- Kurapa Kupisa: Mapaipi anogadziriswa nekupisa kwakadai sekupinza kana kugadzirisa kuti zvinhu zvinake.

- Kupedzisa: Mapaipi anopedzwa nenzira dzakadai sekutwasanudza, kucheka, uye kuongororwa.

- Kuedzwa: Mapaipi aya anoedzwa zvakasiyana-siyana, kusanganisira kuyedzwa kwe hydrostatic, kuyedzwa kwe ultrasonic, uye kuyedzwa kwe eddy current, kuti ave nechokwadi chekuti akagadzirwa zvakanaka.

- Kurapa Pamusoro: Mapaipi anogona kuputirwa kana kugadziriswa kudzivirira ngura uye kunatsiridza chitarisiko chawo.

- Kurongedza nekutumira: Mapaipi acho anorongedzwa zvakanaka uye anotumirwa kune vatengi.

2. Mapaipi esimbi eLSAW (Longitudinal Submerged Arc Welding):

- Kugadzira Mapureti: Mapureti esimbi emhando yepamusoro anogadzirwa kuti ashandiswe mumapombi eLSAW.

- Kugadzira: Maplate anogadzirwa kuita chimiro che "U" uchishandisa muchina wekukombama usati wapinda.

- Kusonta: Maplate akaita se "U" anosonta pamwe chete achishandisa nzira yekusonta arc iri pasi pemvura.

- Kuwedzera: Musono wakasungirirwa unowedzerwa kusvika padhayamita inodiwa uchishandisa muchina wekuwedzera wemukati kana wekunze.

- Kuongorora: Mapaipi anoongororwa kuti aone kana paine zvikanganiso uye kuti aone kana akanyatsojeka.

- Kuongororwa kweUltrasonic: Mapaipi anoongororwa neUltrasonic kuti aone kana paine zvikanganiso mukati.

- Kucheneswa: Migumo yemapaipi yakacheneswa kuti ishandiswe pakuwedera.

- Kupenda neKupenda: Mapaipi anogona kupendwa uye kupendwa zvichienderana nezvinodiwa nevatengi.

- Kurongedza nekutumira: Mapaipi anoiswa mupaketi uye anotumirwa kune vatengi.

3. Mapaipi eSimbi eHFW (High-Frequency Welding):

- Kugadzirira Coil: Coil dzesimbi dzinogadzirwa kuti dzigadzirwe mapaipi eHFW.

- Kugadzira uye Kusonta: Makoiri anogadzirwa kuita chimiro che cylindrical uye anobva asonta achishandisa welding yepamusoro-soro.

- Kudziisa Musono Weld: Musono weld unodziiswa kusvika patembiricha yewelding uchishandisa high-frequency induction heating.

- Saizi: Pombi yakasungirirwa ine saizi yedhayamita neukobvu hunodiwa.

- Kucheka neKupfuudza: Pombi inochekwa kusvika pakureba kwaunoda uye magumo ayo anopfuudzwa kuti ashandiswe pakupfuudza.

- Kuongorora: Mapaipi anoongororwa kuti aone kana paine zvikanganiso uye kuti aone kana akanyatsojeka.

- Kuyedzwa kwemvura inoyerera: Mapaipi anoedzwa kusimba uye kudonha kwemvura achishandisa kuyedzwa kwemvura inoyerera.

- Kupenda neKupenda: Mapaipi anopendwa uye anonyorwa zvichienderana nezvinodiwa nevatengi.

- Kurongedza nekutumira: Mapaipi anoiswa mupaketi uye anotumirwa kune vatengi.

Maitiro aya ekugadzira akadzama anovimbisa mhando yepamusoro uye kuvimbika kwemapaipi esimbi asina musono, LSAW, uye HFW anogadzirwa neWomic Steel, achizadzisa zvinodiwa zvakanyanya zvemaindasitiri akasiyana-siyana.

Kurapa Kwepamusoro:

Kugadziriswa kwesimbi yepombi pamusoro pemvura kwakakosha pakuvandudza kuramba kwayo ngura uye hupenyu hwebasa rayo. Womic Steel inoshandisa nzira dzakasiyana dzekugadzirisa pamusoro pemvura zvichienderana nezvinodiwa nevatengi, zvinosanganisira:

1. Kupisa-kunyika: Pombi yesimbi inonyudzwa mu zinc yakanyungudutswa kuti igadzire zinc-iron alloy protective layer, zvichiita kuti irambe kukora. Kupisa-kunyika kwakakodzera mapaipi echinyakare uye ane pressure shoma.

2. Mapendi ekudzivirira ngura: Mapendi ekudzivirira ngura anowanzo sanganisira epoxy coatings, polyethylene coatings, uye polyurethane coatings. Mapendi aya anodzivirira oxidation uye ngura pamusoro pepombi yesimbi, zvichiita kuti irambe kwenguva refu.

3. Kuputira jecha: Kuputira kwesimbi kunokurumidza kunoshandiswa kuchenesa pombi yesimbi, kubvisa ngura netsvina pamusoro, zvichipa hwaro hwakanaka hwekugadzirisa kuputira kunotevera.

4. Kugadzirisa Kupenda: Pamusoro pepombi yesimbi panogona kupendwa nependi dzinodzivirira ngura, pendi dzeasphalt, nezvimwe zvinodzivirira ngura kuti dzisapararire ngura, zvakakodzera mapaipi epasi pevhu nemapaipi munzvimbo dzegungwa.

Nzira idzi dzekugadzirisa pamusoro dzinodzivirira simbi yemapaipi kubva mukuora nekukuvadzwa, zvichiita kuti ive yakavimbika uye inogara kwenguva refu munzvimbo dzakasiyana-siyana dzakaoma.

Kurongedza uye Kutakura:

Womic Steel inovimbisa kurongedza kwakachengeteka uye kutakurwa kwakavimbika kwesimbi yemapaipi, ichipa sarudzo dzinochinjika kuti dzigutse zvinodiwa nevatengi vakasiyana-siyana:

1. Kutakura Zvinhu Zvikuru: Kune vanotenga zvinhu zvakawanda, simbi yemapaipi inogona kutumirwa yakawanda uchishandisa nhumbi dzakagadzirwa. Simbi yacho inotakurwa zvakananga mungarava isina kurongedza, yakakodzera kutakurwa kwezvinhu zvakawanda zvisingadhuri.

2. LCL (Mutoro Mudiki pane Wemidziyo): Kune maodha madiki, simbi yepombi inogona kutumirwa semidziyo yeLCL, uko maodha madiki akawanda anosanganiswa kuita mudziyo mumwe chete. Nzira iyi inoshanda zvishoma kana zvinhu zvidiki zviri mumidziyo uye inopa nguva yekutumira inochinjika.

3. FCL (Mutoro Wemidziyo Yakazara): Vatengi vanogona kusarudza kutumira kweFCL, uko mudziyo wakazara wakatsaurirwa kuodha kwavo. Nzira iyi inopa nguva yekufambisa nekukurumidza uye inoderedza njodzi yekukuvara panguva yekubata.

4. Kutakura Zvinhu Nemhepo: Kune vanoraira nekukurumidza, kutakurwa kwezvinhu nemhepo kunowanikwa kuti kutumirwe nekukurumidza. Kunyange zvazvo kuchidhura kupfuura kutakurwa mugungwa, kutakurwa kwezvinhu nemhepo kunopa kutakurwa nekukurumidza uye kwakavimbika kwezvinhu zvinotumirwa zvine hanya nenguva.

Womic Steel inoita kuti zvinhu zvese zvinotumirwa zvichengetedzwe zvakanaka kuti zvisakuvara panguva yekufambisa. Simbi inowanzo kuputirwa nezvinhu zvinodzivirira uye inosungirirwa mumagaba kana pamapallets kuti ive nechokwadi chekuti zvinhu zvagadzikana panguva yekufambisa. Pamusoro pezvo, kambani inoshanda pamwe chete nevanoshanda navo mukutakura zvinhu vane mukurumbira kuti ive nechokwadi chekuti zvinhu zvinotumirwa nenguva uye kuti zvinhu zvinofambiswa zvakanaka.

Maitiro Ekushandisa:

Mapaipi emuchina eAPI 5L anogadzirwa neWomic Steel anoshandiswa zvakanyanya mumaindasitiri epeturu negasi rechisikigo pakufambisa mafuta, gasi, nezvimwe zvinwiwa. Anoshandiswawo mune mamwe maindasitiri akasiyana-siyana akadai sekugadzirisa makemikari, kugadzira magetsi, uye kuvaka.

Mhedziso:

Womic Steel ikambani inovimbwa nayo yekugadzira mapaipi emhando yeAPI 5L, ichipa zvigadzirwa zvemhando yepamusoro zvinosangana nezvinodiwa zvakanyanya zvemaindasitiri epetroleum negasi rechisikigo. Iine chinangwa chemhando yepamusoro, kuvimbika, uye kugutsikana kwevatengi, Womic Steel inoramba iri sarudzo inofarirwa nevatengi pasi rese.

Nguva yekutumira: Kurume-22-2024