1. Pfupiso yeChigadzirwa

Womic Steel ikambani inovimbwa nayo yekugadzira mapaipi emhangura emhando yepamusoro anoenderana neASTM B88mitemo, kunyanya iyoRudzi Ltsanangudzo yakagadzirwa kubvaC12200 (phosphorus-deoxidized, phosphorus yakasara yakawanda)mhangura. Mapaipi aya emhangura anoshandiswa zvakanyanya mupombi dzemvura, HVAC, dziviriro yemoto, gasi, uye masisitimu emagetsi akajairikanekuda kwekudzivirira kwavo ngura, kugara kwenguva refu, uye kugona kwavo kugadzira zvinhu.

Mhangura yeC12200 ine huwandu hwakawanda hwemhangura yakachena uye huwandu hushoma hwephosphorus, zvichiita kuti ikwanise kusvetwa uye irambe ichirwisa hydrogen. Mapaipi emhando yeL ane chiyero chakanaka pakati pehukobvu hwemadziro nehuremu, zvichipa kuvimbika mukuisa pamusoro pevhu nepasi pevhu.

2. Rudzi rweKugadzira

- Dhayamita Yekunze (OD):6 mm kusvika 219 mm

- Ukobvu hwemadziro (WT):0.3 mm kusvika 10 mm

- Kureba:Hurefu hwakajairika hwe3m, 5m, 6m, nekureba kwakagadzirirwa kunowanikwa kana wakumbira

- Machubhu Akamonererwa:Inowanikwa muMakoiri e25m kana 50myekuiswa kunochinjika muma "heat exchangers"

- Kuguma Kwekupedzisira:Kumucheto kusina kujeka, kwakacheneswa uye kwakabviswa tsvina; kunowanikwa nevharo kana kuti pasina

3. Kushivirira Kwakakura (ASTM B88 C12200 Machubhu Emhangura)

Womic Steel inoita kuti zvive nyore kushandisa divi rimwe cheteC12200machubhu anoenderana neASTM B88mitemo. Zvinotevera zvinobvumidzwa zvinoshanda:

ASTM B88 - Tafura 1: Zviyero, Kurema, uye Kushivirira kweSaizi dzeTubhu reMhangura

| Saizi Yepamusoro (mukati) | Dhayamita yekunze (mukati) | Kushivirira kweOD (Kwakabviswa) | Kushivirira kweOD (Kwakatorwa) | Rusvingo rwemhando K (mukati) | Rudzi rweK Tol. (mukati.) | Rudzi rweL Wall (mukati) | Rudzi rweL Tol. (mukati.) | Rudzi M Rusvingo (mukati) | Nyora M Tol. (mukati.) |

| 1/4 | 0.375 | 0.002 | 0.001 | 0.035 | 0.0035 | 0.03 | 0.003 | C | C |

| 3/8 | 0.5 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.035 | 0.004 | 0.025 | 0.002 |

| 1/2 | 0.625 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.04 | 0.004 | 0.028 | 0.003 |

| 5/8 | 0.75 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.042 | 0.004 | C | C |

| 3/4 | 0.875 | 0.003 | 0.001 | 0.065 | 0.006 | 0.045 | 0.004 | 0.032 | 0.003 |

| 1 | 1.125 | 0.0035 | 0.0015 | 0.065 | 0.006 | 0.05 | 0.005 | 0.035 | 0.004 |

| 1 1/4 | 1.375 | 0.004 | 0.0015 | 0.065 | 0.006 | 0.055 | 0.006 | 0.042 | 0.004 |

| 1 1/2 | 1.625 | 0.0045 | 0.002 | 0.072 | 0.007 | 0.06 | 0.006 | 0.049 | 0.005 |

| 2 | 2.125 | 0.005 | 0.002 | 0.083 | 0.008 | 0.07 | 0.007 | 0.058 | 0.006 |

| 2 1/2 | 2.625 | 0.005 | 0.002 | 0.095 | 0.01 | 0.08 | 0.008 | 0.065 | 0.006 |

| 3 | 3.125 | 0.005 | 0.002 | 0.109 | 0.011 | 0.09 | 0.009 | 0.072 | 0.007 |

| 3 1/2 | 3.625 | 0.005 | 0.002 | 0.12 | 0.012 | 0.1 | 0.01 | 0.083 | 0.008 |

| 4 | 4.125 | 0.005 | 0.002 | 0.134 | 0.013 | 0.11 | 0.011 | 0.095 | 0.01 |

| 5 | 5.125 | 0.005 | 0.002 | 0.160 | 0.016 | 0.125 | 0.012 | 0.109 | 0.011 |

| 6 | 6.125 | 0.005 | 0.002 | 0.192 | 0.019 | 0.14 | 0.014 | 0.122 | 0.012 |

| 8 | 8.125 | 0.008 | 0.002/-0.004 | 0.271 | 0.027 | 0.2 | 0.02 | 0.17 | 0.017 |

| 10 | 10.125 | 0.008 | 0.002/-0.006 | 0.338 | 0.034 | 0.25 | 0.025 | 0.212 | 0.021 |

| 12 | 12.125 | 0.008 | 0.002/-0.006 | 0.405 | 0.04 | 0.28 | 0.028 | 0.254 | 0.025 |

A Avhareji yedhayamita yekunze yechubhu iavhareji yedhayamita yepamusoro uye yepasi pedhayamita yekunze, sezvinotsanangurwa pane chero chikamu chimwe chete chechubhu.

B Kutsauka kwakanyanya pane imwe nzvimbo.

C Inoratidza kuti zvinhu zvacho hazviwanzo kuwanikwa kana kuti hapana kushivirira kwakasimbiswa

Kushivirira uku kunoita kuti machubhu asanganiswekunyatsorongeka uye zvinodiwa zvemhando yepamusoro, zvichiita kuti zvikodzeremashandisirwo anodiwa mumaindasitiri nemugungwa.

3. Kuumbwa kweMakemikoro (C12200 - ASTM B88)

Chinhu Kuumbwa (% nehuremu)

Mhangura (Cu) MinB≥ 99.9 (kusanganisira sirivha)

Phosphorus (P) 0.015 – 0.040

Okisijeni inofanira kunge iri 10 ppm max.

B Mhangura + sirivha ≤ 0.04

Kuwanda kwephosphorus kunovandudza kuchinjika kwesimbi uye kuramba kupwanyika kwesimbi, ukuwo kuchichengetedza kupisa kwakanyanya uye kufambisa magetsi.

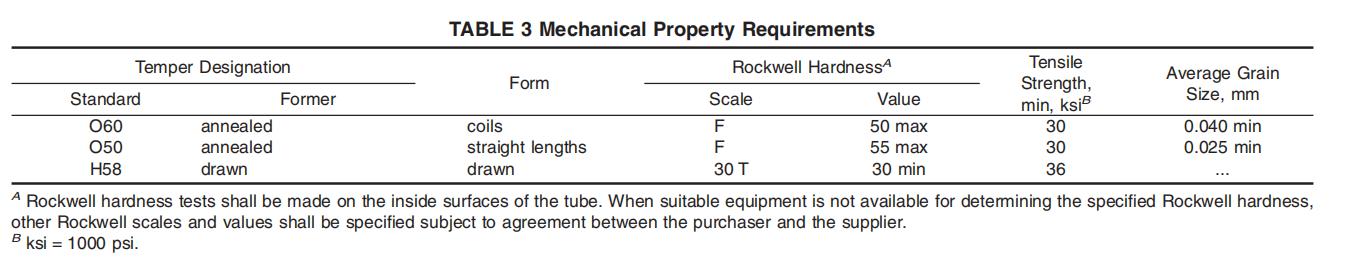

4. Zvimiro zveMichina

Pombi dzemhangura dzakasimba dzerudzi rweL dzinowanzo pihwa muchimiro chakaoma (chakadhonzwa), dzakakodzera masisitimu ekumanikidza uye kuiswa zvakananga.

5. Mamiriro Ekutumira

Womic Steel inopa mapaipi emhangura emhando yeL mumamiriro ezvinhu anotevera:

Hasha Dzakasimba (H58):Kureba kwakatwasuka kwehurongwa hwekumanikidza

Kupisa Kwemhepo (O60):Inowanikwa kana yakumbirwa kune mafomu anoda kukotama nekuumbwa

6. Maitiro Ekugadzira

Womic Steel inoita kuti chigadzirwa chive chakanyatsojeka uye chemhando yepamusoro kuburikidza nematanho anotevera:

- Kunyungudutsa & Kukanda:Mhangura yakachena kwazvo inonyungudutswa yokandwa mumabhillets.

- Kubvisa:Mabhiritsi anoburitswa kuita chimiro chechubhu.

- Mufananidzo Unotonhora:Machubhu anokweverwa kusvika pahukuru hwekupedzisira uye ukobvu.

- Kunyungudutsa (sarudzo):Kana zvichidikanwa, pisa mushonga wekupisa kuti usanyanya kutonhora.

- Kururamisa & Kucheka:Mapaipi anochekwa zvichienderana nehurefu hwakajairwa kana hwakatarwa.

- Kuchenesa & Kuongorora:Nzvimbo dzemukati nedzekunze dzinocheneswa uye dzinoongororwa.

- Kumaka & Kurongedza:Mapaipi ane ASTM B88, mhando, uye saizi yekutevera.

7. Kuedza & Kuongorora

Womic Steel inovimbisa mwero wepamusoro-soro nekuitakuyedzwa kwakasimba uye kuongororwa, kusanganisira:

- Kuongorora Kuumbwa Kwemakemikari:Kuongorora uchishandisa spectrographic kana wet chemical analysis

- Kuedzwa kweKusimba:Kuve nechokwadi chekuti simba uye kureba zvinosangana nezvinodiwa zveASTM B88

- Kuedzwa kweKuoma:Yakayerwa uchishandisaNzira yeVickers

- Muedzo weKuwedzera Kutyaira:Kuwedzera kwemugumo wechubhu ne30%uchishandisa45° mandrel ine denderedzwa remakona

- Muedzo weKubata-bata:Kuongororwa kwekuchinjika uye kuramba kutsemuka

- Bvunzo yeEddy Current (ECT):Kuwanikwa kwezvikanganiso pamusoro nepasi pevhu

- Kuedzwa kweHydrostatic Pressure:Kuve nechokwadi chekuti machubhu anoramba aripokumanikidzwa kwemukati pasina kubuda kwemvura

8. Kuenzanisa

Kutora sampuli nekuyedza kunoitwa zvichienderana neASTM B88 uye maitiro emukati eQA. Mienzaniso yekuyedza inosarudzwa zvisina tsarukano kubva muchikamu chimwe nechimwe che:

l Zviri mukati memakemikari

l Zvimiro zveMichina

Kururama kwehukuru hwe l

l Mamiriro epamusoro

9. Kurongedza

Kuve nechokwadi chekutikubata nekufambisa zvakachengeteka, Womic Steel inopamhinduro dzakasimba dzekurongedza, kusanganisira:

- Kuputira Kunodzivirira Kuoxidation:Rudzi rwekudzivirira rwakashandiswa kudzivirira ngura panguva yekuchengetera nekufambisa

- Magumo Ekupedzisira:Zvivharo zvepurasitiki kana zvesimbi pamativi emachubhu kudzivirira kusvibiswa

- Kubatanidza:Tambo dzakabatana nepurasitiki kana simbi kuti dzigadzikane

- Kugadzira Matanda:Yakaputirwa mukatimabhokisi emapuranga asinganyungudikeine furo rekudzivirira

- Kunyora mazita:Paketi imwe neimwe yakanyorwa kutiOD, WT, urefu, hunyoro, nhamba yebatch, uye zuva rekugadzira

10. Kufambisa & Kutakura Zvinhu

Womic Steel inovimbisakutumira panguva yakakodzera uye yakachengetekakuburikidza ne:

- Kutakura Zvinhu Mugungwa:Yakachengetekakutumirwa kwemidziyo kuti iparadzirwe pasi rose

- Kutakura Njanji Nemugwagwa:Kutumirwa kwakavimbika kune vatengi vemunharaunda

- Kubata Kwakakosha:Sarudzo dzinodzorwa nemamiriro ekunze dzekushandisa zvinonzwisisika

- Magwaro Akakwana:KusanganisiraZvitupa zveMill Test (MTC), Mishumo yeKutevedzera Zvinhu, uye Inishuwarenzi

- Kuramba Kukuru Kwengura:Zvakanakiramashandisirwo ekufambisa zvinhu zvemugungwa, makemikari, uye kupisa

- Kugadzira Nemazvo:Zvakasimbakushivirirana kwemativikuti zviite zvakanaka

- Mhinduro Dzakagadzirwa Nemunhu:Saizi, hunyoro, uye machira akagadzirirwa zvinoenderana nezvinodiwa chaizvo

- Kuedzwa Kwakakwana:Kuve nechokwadi chekutevedzera zvizere mitemoASTM B88

- Network Yekugovera Pasirose:Kutumira pasi rose nekukurumidza uye kwakavimbika

11. Mabhenefiti ekusarudza Simbi yeWomic

12. Mashandisirwo

YeduASTM B88 C12200machubhu akanakira:

- Indasitiri yeMarine: Makondensa anotonhorera mumvura yegungwa, mapaipi, uye zvinochinja-chinja kupisa mungarava

- Mafekitori emagetsi:Zvinotonhodza zvemhepo uyemasisitimu ekutonhodza

- Zvirimwa zvekubvisa munyu:Mapaipi anodzivirira ngura ekushandisa mumvura ine munyu

- Kugadziriswa kweMakemikoro:Machubhu ekupisa anodzvanywa zvakanyanya uye anodziya zvakanyanya

- HVAC & Kuisa mufiriji: Makoiri emhepo inotonhodza uye masisitimu ekutonhodza emaindasitiri

Mhedziso

Mapaipi emhangura eWomic Steel eASTM B88 C12200 Type L anopa kushanda kwakanaka, kugara kwenguva refu, uye kuramba ngura, zvichiita kuti ave sarudzo inofarirwa kune akasiyana masisitimu emapaipi. Nekunyatsotevedzera mitemo yeASTM uye kuvimbiswa kwemhando yepamusoro, tinova nechokwadi chekuti kutumirwa kwega kwega kunosangana nezvinodiwa zvepamusoro mukushanda uye kuvimbika.

Tinozvikudza nepfungwa dzedumabasa ekugadzirisa zvinhu, kutenderera kwekugadzira nekukurumidzauyenetwork yekutumira pasi rose, kuve nechokwadi chekuti zvaunoda chaizvo zvinozadzikiswa nemazvo uye neunyanzvi.

Webhusaiti: www.womicsteel.com

Email: sales@womicsteel.com

Nhare/WhatsApp/WeChat: Victor: +86-15575100681 kana Jack: +86-18390957568

Nguva yekutumira: Ndira-21-2026