Chii chinonzi flange?

Flange muchidimbu, izwi rekuti flange, rinowanzoreva muviri wesimbi wakafanana nedhisiki wekuvhura maburi mashoma akasimbiswa, unoshandiswa kubatanidza zvimwe zvinhu, rudzi urwu rwechinhu runoshandiswa zvakanyanya mumichina, saka runotaridzika serusinganzwisisike, chero bedzi richizivikanwa seflange, zita raro rinobva kuflange yeChirungu. Saka kuti pombi nepaipi zvibatanidzwe kumagumo epombi, flange ine mukana, screws dzekugadzira maflange maviri. Yakabatana zvakasimba, pakati peflange nechisimbiso chegasket.

Flange zvikamu zvakaita sedhisiki, zvinonyanya kushandiswa muinjiniya yemapaipi, flange dzinoshandiswa dziri mbiri.

Nezvemhando dzekubatanidza flange, pane zvikamu zvitatu:

- Mapaipi emapaipi

- Gasket

- Kubatana kwebhoti

Kazhinji, pane gasket nebolt zvakawanikwa zvakagadzirwa nezvinhu zvakafanana nechikamu cheflange yepombi. Flanges dzinonyanya kushandiswa isimbi dzisina ngura. Flanges, kune rumwe rutivi, dzinowanikwa mumhando dzakasiyana-siyana dzezvinhu kuitira kuti dzienderane nezvinodiwa nenzvimbo. Zvimwe zvezvinhu zvinonyanya kushandiswa paflange imonel, inconel, uye chrome molybdenum, zvichienderana nezvinodiwa nenzvimbo chaiyo. Sarudzo yakanakisisa yezvinhu inofanira kutsamira parudzi rwesystem yaunoda kushandisa flange ine zvinodiwa zvakananga.

Mhando 7 Dzakajairika dzeFlanges

Kune mhando dzakasiyana dzemaflanges anogona kusarudzwa zvichienderana nezvinodiwa nenzvimbo yacho. Kuti flange ienderane nekugadzirwa kwayo, kushanda kwayo kwakavimbika pamwe nekugara kwenguva refu kunofanirwa kuve nechokwadi uye mutengo wakakodzera unofanirwa kufungwa nezvawo.

1. flange yakarukwa:

Maflange ane shinda, ane shinda muburi reflange, akaiswa shinda dzekunze pakubatanidza. Kubatanidza shinda pano kunofanirwa kudzivirira kusveta welding muzviitiko zvese. Kunonyanya kubatanidzwa nekubatanidza shinda nepombi inofanira kuiswa.

2. Maflange e socket weld

Rudzi urwu rweflange runowanzo shandiswa pamapombi madiki uko dhayamita yenzvimbo yekupisa kwakaderera uye kumanikidzwa kwakaderera kunoratidzwa nekubatana uko pombi inoiswa mukati meflange kuti ive nechokwadi chekubatana ne weld imwe chete kana yakawanda-nzira. Izvi zvinodzivirira zvipingamupinyi zvine chekuita nemagumo ane shinda zvichienzaniswa nedzimwe mhando dzeflange dzakasungirirwa, zvichiita kuti kuiswa kuve nyore.

3. Mapapiro emakumbo

Flange yemakumbo imhando yeflange inoda kuti magumo e stub asungwe pa fitting kuitira kuti ishandiswe ne flange inotsigira kugadzira flange ine flange. Dhizaini iyi yakaita kuti nzira iyi ifadze mumhando dzakasiyana-siyana dzemasystem uko nzvimbo chaiyo iri shoma, kana uko kunodiwa disassembly kakawanda, kana uko kunodiwa kugadzirisa kwakanyanya.

4. Maflange anotsvedza

Maflange anotsvedza akajairika uye anowanikwa muhukuru hwakasiyana-siyana kuti akwane masisitimu ane mwero wekuyerera kwepamusoro uye ma throughputs. Kungofananidza flange nedhayamita yekunze kwepombi kunoita kuti kubatana kuve nyore kuisa. Kuisa maflange aya kune hunyanzvi sezvo zvichida welding ye fillet kumativi ese kuti flange ibatane nepombi.

5. Magirazi asina kupofumadzwa

Marudzi aya eflanges akakodzera kumisa mapombi. Bhodhi remapofu rakaita sedhisiki risina chinhu rinogona kusungwa nemabhaudhi. Kana izvi zvaiswa zvakanaka uye zvabatanidzwa negasket rakakodzera, zvinoita kuti zvive nyore kuvhara uye zviri nyore kubvisa kana zvichidikanwa.

6. Mafuro emutsipa akasungirirwa

Maflange emutsipa weld akafanana zvikuru nemaflange emakumbo, asi anoda kusungirirwa kwebutt kuti aiswe. Uye kushanda kwesystem iyi uye kugona kwayo kukotama kakawanda uye kushandiswa mumasystem ekumanikidza zvakanyanya uye tembiricha yakakwira zvinoita kuti ive sarudzo huru yekuisa mapaipi.

7. Maflanges ehunyanzvi

Rudzi urwu rweflange ndirwo rwakanyanya kuzivikanwa. Zvisinei, kune mhando dzakasiyana-siyana dzeflange dzakagadzirwa kuti dzikwane mashandisirwo akasiyana-siyana uye nharaunda. Kune dzimwe sarudzo dzakasiyana-siyana dzakadai se nipo flanges, weldo flanges, expansion flanges, orifices, long weld necks uye reducer flanges.

Mhando 5 Dzakakosha dzeFlanges

1. WeldoFruvara

Flange yeWeldo yakafanana zvikuru neflange yeNipo sezvo iri musanganiswa weflange dzematako nekubatanidza matavi. Flange dzeWeldo dzinogadzirwa nesimbi imwe chete yakasimba, pane kuti zvikamu zvega zvega zvibatanidzwe pamwe chete.

2. Flange yeNipo

Nipoflange ipaipi yebazi yakakombama pakona yemadhigirii makumi mapfumbamwe, chigadzirwa chinogadzirwa nekubatanidza maflange ekubatanidza matako neNipolet yakagadzirwa. Kunyange zvazvo Nipo flange ichiwanikwa iri simbi yakasimba, hazvinzwisiswi kuti imhando mbiri dzakasiyana dzakasungirirwa pamwe chete. Kuisa Nipoflange kunosanganisira kusundira kuchikamu cheNipolet chemidziyo kuitira kuti pombi imhanye uye kusundira chikamu cheflange kuflange yepombi yakagadzirwa nevashandi vepaipi.

Zvakakosha kuziva kuti maNipo flanges anowanikwa mumhando dzakasiyana dzezvinhu zvakaita sekabhoni, simbi dzekabhoni dzinopisa zvakanyanya uye zvishoma, simbi dzisina ngura, uye nickel alloys. MaNipo flanges anowanzo gadzirwa nekugadzirwa kwakasimbiswa, izvo zvinobatsira kuti awedzere simba remuchina kana tichienzanisa neNipo flange yakajairwa.

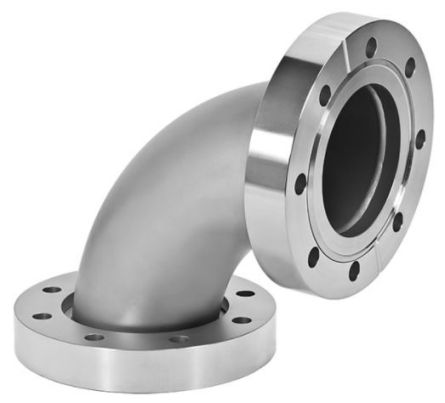

3. Elboflange neLatroflange

Elboflange inozivikanwa semusanganiswa weflange neElbolet nepo Latroflange ichizivikanwa semusanganiswa weflange neLatrolet. Maflange eelbow anoshandiswa kumapaipi emapazi pakona ye45 degrees.

4. Maflange emhete anotenderera

Kushandiswa kwe flanges dze rounding ring ndekwekubatsira kuti maburi emabolt arongwe pakati pe flanges mbiri dzakapakwa, izvo zvinobatsira zvikuru mumamiriro ezvinhu akawanda, akadai sekuiswa kwemapaipi makuru, mapombi emugungwa kana ekunze kwenyika nenzvimbo dzakafanana. Marudzi aya e flanges akakodzera mvura inoda simba mumafuta, gasi, mahydrocarbon, mvura, makemikari nezvimwe zvinoshandiswa pakugadzirisa petrochemical uye mvura.

Kana mapaipi akakura, pombi yacho ine flange ye weld yakajairwa kumucheto mumwe uye flange inotenderera kune mumwe. Izvi zvinoshanda nekungotenderedza flange inotenderera papombi kuitira kuti mushandi awane kurongeka kwemaburi emabhoti nenzira iri nyore uye nekukurumidza.

Mimwe yemitemo mikuru ye flanges dze ring dzinotenderera ndeye ASME kana ANSI, DIN, BS, EN, ISO, nedzimwewo. Imwe yemitemo inonyanya kufarirwa yekushandiswa kwe petrochemical iANSI kana ASME B16.5 kana ASME B16.47. Swivel flanges iflanges dzinogona kushandiswa mumhando dzese dze flange dzakajairwa. Semuenzaniso, weld necks, slip ons, lap joints, socket welds, nezvimwewo, mumhando dzese dzezvinhu, muhukuru hwakasiyana kubva pa 3/8" kusvika 60", uye kumanikidzwa kubva pa 150 kusvika 2500. flanges idzi dzinogona kugadzirwa zviri nyore kubva ku carbon, alloy, uye stainless steels.

5. Maflange ekuwedzera

Maflange ekuwedzera, anoshandiswa kuwedzera saizi yebore yepombi kubva pane imwe nzvimbo kuenda kune imwe kuitira kubatanidza pombi kune chero mimwe michina yemakanika yakaita semapombi, macompressor, nemavharuvhu anowanikwa aine saizi dzakasiyana dzekupinda.

Maflange ekuwedzera anowanzo kuve maflange ane mabutt-welded ane buri guru kwazvo kumucheto usina flanged. Anogona kushandiswa kuwedzera saizi imwe chete kana mbiri kana kusvika masendimita mana pabhore repombi rinoyerera. Mhando idzi dzeflange dzinofarirwa pane kusanganiswa kwezvinoderedza mabutt-weld uye maflange akajairwa nekuti akachipa uye akareruka. Chimwe chezvinhu zvinonyanya kushandiswa pakuwedzera maflange iA105 nesimbi isina ngura ASTM A182.

Maflange ekuwedzera anowanikwa muhuwandu hwemadhigirii uye saizi zvichienderana nezvinodiwa neANSI kana ASME B16.5, izvo zvinonyanya kuwanikwa zviri convex kana flat (RF kana FF). Maflange ekuderedza, anozivikanwawo sereducing flanges, anoshanda basa rakasiyana chaizvo kana tichienzanisa nemaflange ekuwedzera, zvichireva kuti anoshandiswa kuderedza saizi yebore yepombi. Dhayamita yebore yepombi inogona kuderedzwa zviri nyore, asi kwete nehukuru hunopfuura 1 kana 2. Kana kuedza kuderedza kupfuura izvi, mhinduro yakavakirwa pamusanganiswa wezvidzikisi zvakasungirirwa pamatako uye maflange akajairwa inofanira kushandiswa.

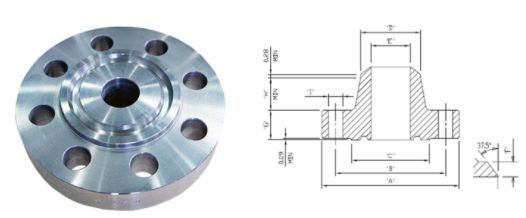

Kukura kweFlange uye Zvakajairika

Pamusoro pemagadzirirwo anoitwa flange, saizi yayo ndiyo inonyanya kukanganisa kusarudzwa kweflange pakugadzira, kuchengetedza uye kugadzirisa sisitimu yepombi. Pane kudaro, kunofanirwa kufungwa nezvekubatana kweflange nepombi nemagasket anoshandiswa kuona saizi yakakodzera. Pamusoro peizvi, zvimwe zvinhu zvakajairika ndeizvi:

- Dhayamita yekunze: Dhayamita yekunze idaro riri pakati pemipendero miviri yakatarisana yechiso cheflange.

- Ukobvu: Ukobvu hunoyerwa kubva kunze kwerim.

- Dhayamita yedenderedzwa rebhoti: Iyi ndiyo daro riri pakati pemaburi ebhoti akayerwa kubva pakati kuenda pakati.

- Saizi yepombi: Saizi yepombi inoenderana neflange.

- Bore reNominal: Bore renominal ndiro saizi yedhayamita yemukati meflange connector.

Kurongwa kweFlange uye Nhamba Yebasa

Maflange anorongwa zvakanyanya nekukwanisa kwawo kutsungirira tembiricha dzakasiyana uye kumanikidzwa. Anoratidzwa nekushandisa mabhii kana zvisungo "#", "lb" kana "class". Aya ma sungo anochinjika uye anosiyanawo zvichienderana nenzvimbo kana mutengesi. Mapoka anozivikanwa akanyorwa pazasi:

- 150#

- 300#

- 600#

- 900#

- 1500#

- 2500#

Kushivirira kwakafanana kwekumanikidzwa uye tembiricha kunosiyana zvichienderana nezvinhu zvinoshandiswa, dhizaini yeflange uye saizi yeflange. Zvisinei, chinongogara chiripo ipfungwa yekumanikidzwa, iyo inoderera sezvo tembiricha ichiwedzera.

Rudzi rweFlange Face

Rudzi rwechiso chinhu chakakosha zvikuru chine chekuita nekushanda kwekupedzisira uye hupenyu hwebasa reflange. Saka, mamwe emhando dzakakosha dzeflange faces anoongororwa pazasi:

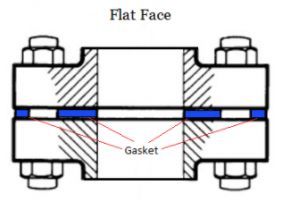

1. Flange Yakatsetseka (FF)

Nzvimbo ye gasket yeflange yakatsetseka iri muchikamu chimwe chete nepamusoro pefuremu yakasungirirwa. Zvishandiso zvinoshandisa flat flanges zvinowanzogadzirwa ne molds kuti zvienderane neflange kana chifukidziro cheflange. Flanges dzakatsetseka hadzifanirwe kuiswa pa inverted side flanges. ASME B31.1 inoti kana uchibatanidza flat cast iron flanges ne carbon steel flanges, face yakasimudzwa pa carbon steel flanges inofanira kubviswa uye full face gasket inodiwa. Izvi zvinoitirwa kudzivirira ma flanges madiki, asina kusimba e cast iron kuti asapinda muvhu rakaumbwa nemhino yakasimudzwa ye carbon steel flange.

Rudzi urwu rwechiso cheflange runoshandiswa mukugadzira michina nemavharuvhu ekushandisa kwese uko simbi yakagadzirwa. Simbi yakakandwa inopfava uye inowanzo shandiswa chete pakushandiswa kwekupisa kwakaderera uye kudzvanywa kwakaderera. Chiso chakati sandara chinobvumira maflange ese maviri kuti abatane zvakakwana pamusoro pese. Flat Flanges (FF) ine nzvimbo yekubata yakaenzana netambo dzebhaudhi dzeflange. Full face washers dzinoshandiswa pakati peflanges mbiri dzakati sandara uye dzinowanzo nyorova. Sekureva kweASME B31.3, flat flanges hadzifanirwe kubatanidzwa neflanges dzakakwira nekuda kwekugona kubuda kwemvura kubva paflange joint inobuda.

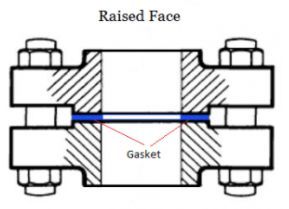

2. Flange Yakasimudzwa (RF)

Flange yakasimudzwa ndiyo inonyanya kushandiswa mukugadzira zvinhu uye inoonekwa zviri nyore. Inonzi convex nekuti chiso chegasket chiri pamusoro pechiso chebolt ring. Rudzi rwega rwekutarisana runoda kushandiswa kwemhando dzakasiyana dzegaskets, kusanganisira dzakasiyana-siyana dze flat ring tabs uye simbi dzakasanganiswa dzakadai se spiral-wound uye double-sheathed forms.

Maflange eRF akagadzirwa kuti awedzere kudzvanyirira panzvimbo diki yegasket, nokudaro achivandudza kudzora kudzvanyirira kwejoinhi. dhayamita nekukwirira zvichienderana nedanho rekudzvanyirira uye dhayamita zvinotsanangurwa muASME B16.5. Danho rekudzvanyirira reFlange rinotsanangura kukwirira kwechiso chiri kusimudzwa. Maflange eRF akagadzirirwa kuwedzera kudzvanyirira panzvimbo diki yegasket, nokudaro achiwedzera kugona kwekutonga kudzvanyirira kwejoinhi. Dhayamita nekukwirira zvichienderana nekirasi yekudzvanyirira uye dhayamita zvinotsanangurwa muASME B16.5. Kuyera kweFlange rekudzvanyirira.

3. Ring flange (RTJ)

Kana chisimbiso chesimbi kubva kusimbi kuenda kusimbi chinodiwa pakati pemaflange akabatana (chinova chinodiwa kuti pave nekumanikidzwa kwakanyanya uye tembiricha yepamusoro, kureva, pamusoro pe700/800 C°), Ring Joint Flange (RTJ) inoshandiswa.

Chinongedzo chemubato werin'i chine mugero wakatenderera unobata gasket yerin'i (yakaita denderedzwa kana kuti ine denderedzwa).

Kana ma flange maviri e ring joint akabatanidzwa pamwe chete obva asimbiswa, simba re bhoti rinoshandiswa rinokanganisa gasket riri mu groove ye flange, zvichiita kuti chisimbiso chesimbi chive chakasimba kwazvo. Kuti izvi zviitike, zvinhu zve gasket ye ring joint zvinofanira kunge zvakapfava (zvakanyanya kupfava) kupfuura zvinhu zve flanges.

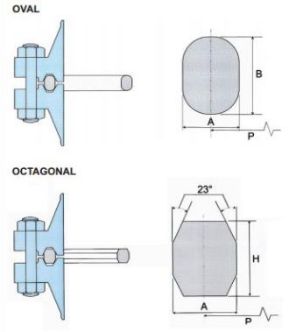

Maflange eRTJ anogona kuvharwa nemagasket eRTJ emhando dzakasiyana (R, RX, BX) uye maprofiles (semuenzaniso, octagonal/elliptical yemhando yeR).

Gasket reRTJ rinonyanya kushandiswa iR rine chikamu che octagonal cross-section, sezvo richivimbisa chisimbiso chakasimba (chikamu che oval ndicho chekare). Zvisinei, dhizaini ye "flat groove" inogamuchira marudzi ese eRTJ gaskets ane chikamu che octagonal kana oval cross-section.

4. Maflange erurimi negorova (T & G)

Maflange maviri erurimi negoronga (T & G faces) anonyatsoenderana: rimwe flange rine rin'i yakasimudzwa uye rimwe rine maburi parinokwana zviri nyore (rurimi runopinda mugoronga rovhara joini).

Maflange erurimi negorova anowanikwa muhukuru hukuru nehukuru hudiki.

5. Maflange echirume neechikadzi (M & F)

Kufanana neflange dzerurimi nedzemugero, flange dzechirume nedzechikadzi (mhando dzechiso cheM & F) dzinoenderana.

Imwe flange ine nzvimbo inopfuura nzvimbo yayo yepamusoro, iyo flange yechirume, uye imwe flange ine mipata yakafanana yakagadzirwa pamusoro wakatarisana, iyo flange yechikadzi.

Kupedzisa kweFlange Pamusoro

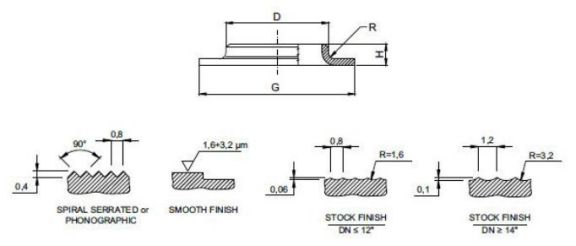

Kuti flange ikwane zvakakwana negasket neflange inosangana, nzvimbo yeflange inoda roughness yakati (RF neFF flange finishes chete). Rudzi rweroughness rweflange face surface ndiyo inotsanangura rudzi rwe "flange finish".

Mhando dzakajairika ndedze stock, concentric serrated, spiral serrated uye smooth flange faces.

Kune magadzirirwo mana ekutanga esimbi dzesimbi, zvisinei, chinangwa chakafanana chemhando ipi zvayo yekugadzirwa kweflange ndechekugadzira hukasha hunodiwa pamusoro peflange kuti ive nechokwadi chekuti flange, gasket uye mating flange zvinokwana zvakanaka.

Nguva yekutumira: Gumiguru-08-2023