1. Nhanganyaya yeMapaipi Ekuchera Anorema Zvikuru

Mapaipi ekuboorera zvinhu zvakakosha zvinobatanidza midziyo yepamusoro nezvishandiso zvepasi.Mapaipi Ekuchera Anorema (HWDP), semapaipi ekuchera akasarudzika, anoshanda sechinhu chinochinja pakati pemapaipi ekuchera akajairwa nemakorari ekudhonza. Kuburikidza nekugadzirwa kwakagadziridzwa kwechivakwa uye zvinhu zvepamusoro, HWDP inoita basa rakakosha mukutakura mutoro, kudzikamisa kudedera, uye kugadzikana kwenzira dzetsime mumamiriro ezvinhu akaomarara ekudhonza.

Zvinhu Zvikuru zveKugadzira:

Kuchinja Kwechimiro: Mabhiriji anodhonza mapombi "anochinjika" uye makorari "akaoma" ekudhonza mabhomba, zvichideredza kushushikana panzvimbo dzinosangana mabhomba.

Ukobvu hwemadziro hwakavandudzwa: ukobvu hwakapetwa kaviri kusvika katatu kupfuura mapaipi ekuboorera akajairwa ukuwo dhayamita yekunze yakafanana (semuenzaniso, φ50 mm, φ89 mm) kuti ienderane nekushanda kwayo.

Mashandisirwo Akawanda: Inotsiva mabhora ekuboorera mukuboorera kwemaburi madiki, inoderedza njodzi dze torque nemapaipi akanamatira mumatsime akananga, uye inogonesa kudzora kwehuremu pahuremu (WOB) nemazvo.

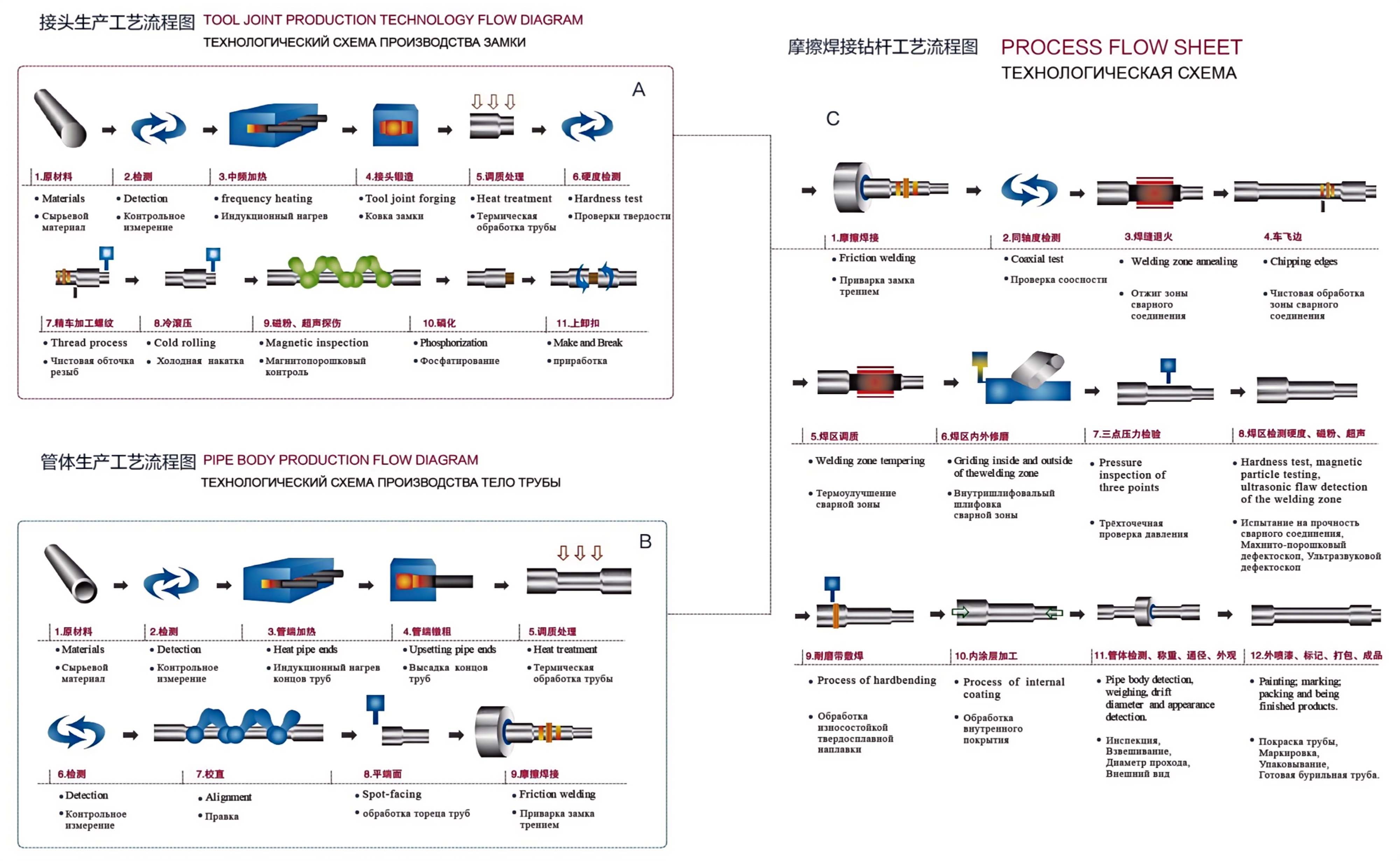

2. Kugadzira Zvivakwa: Kuvimbisa Simba uye Kuramba Kupfeka

2.1 Maumbirwo eMuviri wePaipi

Dhizaini Isingafadzi: Kukanganiswa kwemukati, kwekunze, kana kwakabatana pamagumo emapaipi kuti kuwedzere kuramba kudzvanywa uye kushanda zvakanaka kwekuneta.

Kushungurudzika Kwemukati: Inochengetedza dhayamita yekunze yemigero mitete.

Kushungurudzika Kwekunze: Inowedzera simba rekutakura zvinhu zvematsime akamira.

Kushungurudzika Kwakabatana: Yakanakira nzvimbo dzakanyanya kushata dzakadai sematsime akadzika zvakanyanya.

Kusarudzwa Kwezvinhu: Ma alloys ane simba guru (semuenzaniso, 4145H MOD) ane simba rekugadzira rinotangira pa55,000 kusvika 110,000 KSI.

2.2 Tekinoroji yekubatanidza zvishandiso

Majoini eChishandiso Akawedzerwa: Wedzera nzvimbo yekubata kuti ugovane kushushikana, kudzvanywa, uye mitoro yekutenderera.

Nzira dzekubatanidza:

Kubatana Kwakabatana: API kana shinda dzine mapendekete maviri dzine zvinovhara mvura kudzivirira kubuda kwemvura.

Zvivako Zvakasungirirwa: Majoini akabatanidzwa akagadzirwa kuti ashandiswe pakumanikidzwa kwakanyanya.

2.3 Hardband Inodzivirira Kupfekwa

Zvinhu: Tungsten carbide (HRC ≥60)

Mabasa:Inoderedza kupera kwemuviri wepombi ne50% mumagonhi akatambarara.

Inowedzera kukweshana kwekusimbisa tambo dzebooresa uye kudzora nzira dzekufamba nadzo.

3. Mabasa Ekutanga: Kubva Pakuderedza Kushushikana Kuenda Pakugadzikana Kwemuviri

3.1 Kugadzirisa Kushushikana

Kunyudzwa kweKudedera: Zvikamu zvakakanganiswa nezvinhu zvinonamira zvinoshandura kutenderera kwekora yekuboorera kuita kupararira kwesimba re elastic.

Kuderedza torque: Majoini ezvishandiso akawedzerwa anoparadzirazve kushushikana kwe torsional, zvichideredza kuneta mumapaipi akajairwa.

3.2 Kugadzirisa WOB

Kubatsira Kwehuremu: Huremu hwepakati (semuenzaniso, 38 kg/m ye φ89 mm HWDP) pakati pemapaipi ekuboorera nemakora.

Kudzora Kuchinjika: Inogadzirisa WOB ye shale formations (inodzivirira stuck pombi) uye hard-rock layers (inowedzera kupinda).

3.3 Kutendeseka kweTsambo neWellbore

Kugadzikana Kwekutungamira: Kuisa simbi dzakasimba kunoderedza kutenderera kwetambo dzekuchera, zvichiita kuti nzira dzematsime dzirambe dzakarongwa.

Kurwisa Kuputsika: Inoderedza kukwira kwesimba kubva pakukombama, ukuwo kutenderera kwevhu kuchivimbisa kuchena kwemaburi.

4. Mashandisirwo Anoshanda

4.1 Kuchera Matsime Akadzika Zvakanyanya

Chidzidzo Chenyaya: Tashen-1 Well (kudzika kwe 8,408 m, >200°C, kumanikidzwa kwe 140 MPa).

Kushanda: Ma alloys anodzivirira kupisa kwakanyanya uye magadzirirwo akakwidibira akakunda maumbirwo akashata uye kushushikana kwecyclic.

4.2 Mamiriro Ezvinhu Anonetsa

Nzvimbo dzeGasi Rinovava: Jiaoye-1HF Well (Fuling Shale Gas Field) yakashandisa alloys uye coatings dzisingakanganiswi nengura kurwisa H₂S.

Matsime Akananga/Akatwasuka: HWDP yerudzi rweSpiral yakaderedza kukweshana uye yakawedzera kudzora kwakanangana.

5. Kufambira Mberi Kwetekinoroji

5.1 Kugadzira Zvinhu Zvitsva

Kurapa Kupisa: Kudzima nekudzikamisa kuti pave nekusimba kwesimba.

Kuvimbisa Hunhu Hwakanaka: Kuongororwa kwe ultrasonic 100% (UT) uye kuongororwa kwe magnetic particle (MPI).

5.2 Kugadzira Zvinhu Zvine Hungwaru

Kubatanidzwa kweMES/ERP: Kutevedza kwakazara kubva paodha kusvika pakutumira.

Sarudzo dzekugadzirisa: Zvinobatanidza mapendekete maviri, hardband yakareba, uye mapurasitiki emukati.

6. Maitiro Ekugadzira

Kusarudzwa Kwezvinhu: 4145H MOD alloy steel bars.

Kugadziriswa kweMapaipi: Kuboora → kugadzira zvinhu zvakakanganiswa → kurapwa kwekupisa.

Kugadzira Chishandiso Chekubatanidza: Kugadzira → kutenderedza shinda inotonhora → kuposphating.

Kushongedza/Kuunganidza: Kukwesha friction kana machining integral.

Kudzora Hunhu: Kuyerwa kweukobvu hweUT, kuyedzwa kwekuoma, kusimbiswa kwekumanikidzwa.

Kurapa Kwepamusoro: Kushandiswa kwesimbi dzakasimba uye machira ekudzivirira ngura.

Mhedziso

Senzira huru yekuvandudza tekinoroji yemazuva ano yekuchera, HWDP inosanganisa hunyanzvi hwekuvaka nesainzi yezvinhu kuti iwedzere kuchengetedzeka uye kushanda zvakanaka kwekuchera. Kubva pamatsime akadzika zvakanyanya kusvika kumaumbirwo anoparadza, basa rayo riviri se "shanduko inochinjika" uye "rutsigiro rwakasimba" rinoramba richisundira miganhu yekutsvaga mafuta negasi.

Sarudza Womic Steel Group semubatsiri wako akavimbika wemapaipi ekuboorera uye mashandiro ekutumira asingakundike. Tinokugamuchirai!

Webhusaiti: www.womicsteel.com

Email: sales@womicsteel.com

Nhare/WhatsApp/WeChat: Victor: +86-15575100681 kana Jack: +86-18390957568

Nguva yekutumira: Kubvumbi-11-2025