Simbi isina ngura ipfupiso yesimbi isingapindi acid, mhepo, utsi, mvura nezvimwe zvisina simba zvinokanganisa kana simbi isingapindi stainless inozivikanwa sesimbi isingapindi stainless; uye haipindi makemikari anorwisa ngura (acids, alkalis, munyu, nezvimwe zvinokonzerwa nemakemikari) ngura yesimbi inonzi simbi isingapindi acid.

Simbi isina ngura zvinoreva mhepo, utsi, mvura nezvimwe zvisina simba zvinoparadza uye acids, alkalis, munyu nezvimwe zvinokonzerwa nemakemikari zvinoparadza ngura zvesimbi, inozivikanwawo sesimbi isingachinji acid. Mukuita, kazhinji simbi isingachinji inonzi stainless corrosive corrosion inonzi stainless steel, uye chemical media inodzivirira corrosion inonzi acid-resistant steel. Nekuda kwekusiyana kwemakemikari ari maviri aya, yekutanga haisi hazvo inodzivirira corrosion yemakemikari, nepo yekupedzisira ichiwanzova isina stainless. Kudzivirira corrosion kwesimbi isingachinji kunoenderana nezvinhu zviri musimbi.

Kupatsanurwa Kwakafanana

Zvinoenderana nesangano resimbi

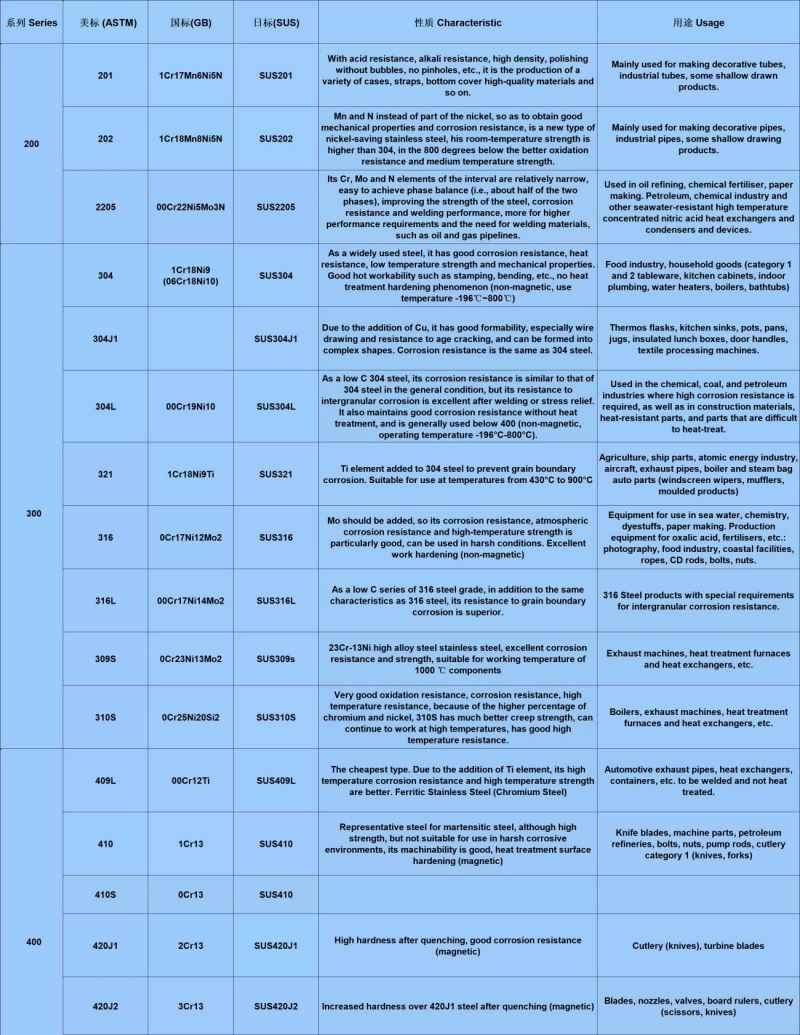

Kazhinji, maererano nesangano resimbi, simbi dzisingapindi simbi dzinoshandiswa zvakakamurwa kuita zvikamu zvitatu: simbi dzisingapindi simbi dzinoshandiswa austenitic, simbi dzisingapindi simbi dzinoshandiswa ferritic uye simbi dzisingapindi simbi dzinoshandiswa martensitic. Zvichibva pakurongeka kwesimbi dzemhando nhatu idzi, simbi dzine duplex, simbi dzisingapindi simbi dzinoomesa mvura uye simbi dzine alloy yakawanda dzine iron isingasviki 50% dzinobva kune zvinodiwa nezvinangwa chaizvo.

1. Simbi isina ngura yeAustenitic

Chimiro chekristaro che cubic centred kusvika kumeso che austenitic organization (CY phase) chinodzorwa ne non-magnetic, kunyanya kuburikidza nekushanda kwechando kuti chisimbi isimbi isingasvibi. The American Iron and Steel Institute yakatora 200 ne300 series of numberable labels, dzakadai se304.

2. Simbi isina ngura yeFerritic

Matrix kusvika kuchimiro chekristaro checubic chakatarisana nemuviri cheferrite (chikamu) ndicho chikuru, chine magineti, kazhinji hachigoni kuomeswa nekupisa, asi kushanda nechando kunogona kuita kuti ive simbi isina ngura yakasimbiswa zvishoma. American Iron and Steel Institute yakanyora 430 na446 yezita racho.

3. Simbi isina ngura yeMartensitic

Matrix iyi ine martensitic organization (body-centered cubic kana cubic), ine magnetic, kuburikidza nekupisa inogona kugadzirisa hunhu hwayo hwesimbi isingatsvi. American Iron and Steel Institute kune 410, 420, uye 440 manhamba akanyorwa. Martensite ine austenitic organization pakupisa kwakanyanya, iyo inogona kushandurwa kuita martensite (kureva kuomarara) kana yatonhodzwa kusvika pakupisa kwemukamuri pachiyero chakakodzera.

4. Simbi isina ngura yerudzi rweAustenitic inonzi ferrite (duplex)

Matrix ine austenitic neferrite two-phase organization, iyo iri mukati me lesser phase matrix inowanzo pfuura 15%, ine magnetic, inogona kusimbiswa nekushanda kwesimbi isina ngura inotonhora, 329 isimbi isina ngura yakajairika ine duplex. Kana ichienzaniswa ne austenitic stainless steel, duplex steel high strength, resistance to intergranular corrosion uye chloride stress corrosion uye pitting corrosion zviri nani zvikuru.

5. Simbi isina ngura inoomesa mvura

Matrix iyi inorongeka ne austenitic kana martensitic, uye inogona kuomeswa ne precipitation hardiness treatment kuti iomeswe ne stainless steel. American Iron and Steel Institute yakatevedzana ne600 series of digital labels, dzakadai se630, kureva 17-4PH.

Kazhinji, pamusoro pema alloys, kuramba ngura kwe austenitic stainless steel kwakanyanya kunaka, munzvimbo isingakanganisi zvakanyanya, unogona kushandisa ferritic stainless steel, munzvimbo dzine ngura zvishoma, kana zvinhu zvichidikanwa kuti zvive nesimba rakawanda kana kuomarara kwakanyanya, unogona kushandisa martensitic stainless steel uye precipitation stainless steel hardening.

Hunhu uye mashandisirwo

Maitiro epamusoro

Musiyano wekukora

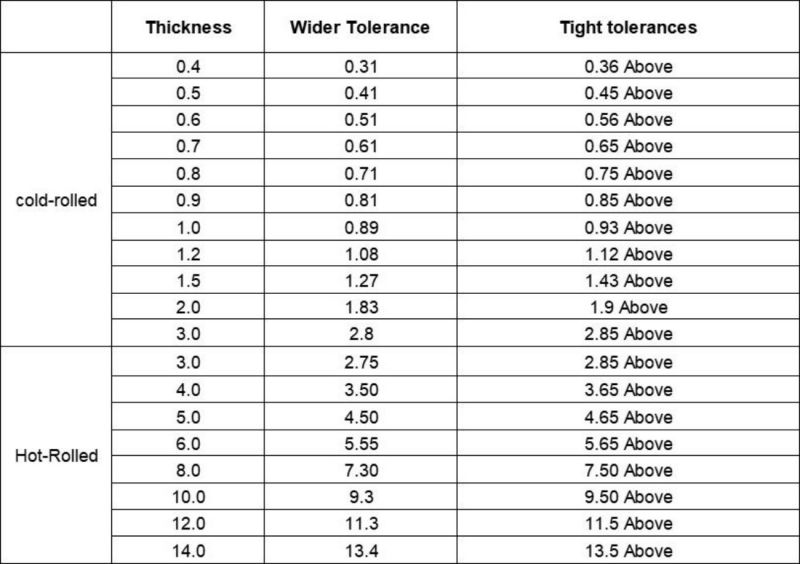

1. Nekuti michina yesimbi iri mukutenderera, mipumburu inodziiswa nekuchinja kudiki, zvichikonzera kutenderera ukobvu hweplate, kazhinji huchikora pakati pemativi maviri eplate. Mukuyera ukobvu hweplate, mitemo yenyika inofanira kuyerwa pakati peplate musoro.

2. Chikonzero chekushivirirana kwacho chakavakirwa pamusika uye zvinodiwa nevatengi, zvinowanzo patsanurwa muzvikamu zvikuru nezvidiki.

V. Zvinodiwa pakugadzira, kuongorora

1. Pombi yepombi

① majoini epachubhu akasanganiswa kuti aonekwe ne 100% ray kana UT, nhanho inokodzera: RT: Ⅱ UT: nhanho Ⅰ;

② Kuwedzera kune simbi isina ngura, pombi yeplate yakasanganiswa inobatsirawo pakupisa;

③ Kutsauka paupamhi hwebhiriji repachubhu nepuratifomu: zvichienderana nefomura yekuverenga upamhi hwebhiriji regomba: B = (S - d) - D1

Upamhi hushoma hwebhiriji rine gomba: B = 1/2 (S - d) + C;

2. Kurapa kupisa kwebhokisi rechubhu:

Simbi yekabhoni, simbi ine alloy yakaderera yakasungirirwa nechikamu chakapatsanurwa chebhokisi repombi, pamwe nebhokisi repombi remaburi emativi anopfuura 1/3 yedhayamita yemukati mebhokisi repombi yesilinda, mukushandiswa kwewelding yekuderedza kushushikana kwekupisa, flange uye chikamu chekuvharira chinofanira kugadziriswa mushure mekupisa.

3. Kuedzwa kwekumanikidzwa

Kana kumanikidzwa kwekugadzirwa kweganda remakombo kuri pasi pane kumanikidzwa kwemuchina wechubhu, kuitira kutarisa mhando yekubatana kwechubhu inochinja kupisa uye chubhu.

① Kumanikidzwa kwepurogiramu yeShell kuwedzera kumanikidzwa kwekuyedza nepurogiramu yepombi zvinoenderana nekuyedza kwehydraulic, kuti uone kana kubuda kwepombi kwakaitika. (Zvisinei, zvakakosha kuve nechokwadi chekuti kumanikidzwa kukuru kweganda panguva yekuyedza kwehydraulic kuri ≤0.9ReLΦ)

② Kana nzira iri pamusoro apa isina kukodzera, goko rinogona kuedzwa ne hydrostatic zvichienderana nekumanikidzwa kwekutanga mushure mekupfuura, uye wozoongorora goko re ammonia leakage kana halogen leakage test.

Isimbi isina ngura yerudzii isingakuvadzi nyore?

Pane zvinhu zvitatu zvikuru zvinokanganisa ngura yesimbi isina ngura:

1. Zviri mukati mezvinhu zvinosanganisa simbi. Kazhinji, zviri mukati me chromium musimbi ye10.5% hazviremi kuita ngura. Kana chromium ne nickel zvikaramba ngura zvakanyanya, zvakaita se 304 nickel content ye 85 ~ 10%, chromium content ye 18% ~ 20%, simbi isina ngura yakadaro haisi ngura.

2. Maitiro ekunyungudutsa emugadziri anokanganisawo kuramba kwesimbi isingatsvi. Tekinoroji yekunyungudutsa yakanaka, michina yepamusoro, tekinoroji yepamusoro, chirimwa chikuru chesimbi isingatsvi, zvese zviri mukutonga kwezvinhu zvinosanganisa alloying, kubviswa kwetsvina, kudzora tembiricha yekutonhodza billet kunogona kuvimbiswa, saka mhando yechigadzirwa yakagadzikana uye yakavimbika, mhando yakanaka yemukati, haisi nyore kuita ngura. Kusiyana neizvi, mimwe michina midiki yesimbi inodzokera shure, tekinoroji yekudzokera shure, maitiro ekunyungudutsa, tsvina haigone kubviswa, kugadzirwa kwezvigadzirwa kuchaita ngura zvisingadzivisike.

3. Nzvimbo yekunze. Nzvimbo yakaoma uye ine mhepo inofefetera haisi nyore kuita ngura, nepo hunyoro hwemhepo, mamiriro ekunze anonaya nguva dzose, kana mhepo ine acidity uye alkalinity yenzvimbo iri nyore kuita ngura. 304 simbi isina ngura, kana nzvimbo yakapoteredza isina kunaka zvakanyanya, ine ngurawo.

Mavara engura esimbi isina ngura ungagadzirisa sei?

1. Nzira yemakemikari

Nekusanganisa ngura kana spray yekubatsira zvikamu zvayo zvakaora kuti zvidzore kugadzirwa kwe chromium oxide film kuti idzorere kuramba kwayo ngura, mushure mekusanganisa, kuitira kubvisa zvese zvinosvibisa uye acid residues, zvakakosha zvikuru kusukurudza nemvura zvakanaka. Mushure mekunge zvese zvagadziriswa uye zvagadziriswazve nemidziyo yekupukuta, zvinogona kuvharwa newakisi yekupukuta. Kune nzvimbo dzine ngura diki dzinogona kushandiswawo peturu ye1:1, musanganiswa wemafuta nejira rakachena kuti ubvise ngura.

2. Nzira dzemakanika

Kuchenesa jecha, kuchenesa negirazi kana ceramic particles kuputika, kuparadzwa, kukwesha nekupukuta. Nzira dzemichina dzinogona kubvisa kusvibiswa kunokonzerwa nezvinhu zvakambobviswa, zvinhu zvekukwesha kana zvinhu zvakaparadzwa. Mhando dzese dzekusvibiswa, kunyanya simbi dzekunze, dzinogona kukonzera ngura, kunyanya munzvimbo dzine hunyoro. Nokudaro, nzvimbo dzakacheneswa nemechanical dzinofanira kucheneswa zviri pamutemo mumamiriro ekunze akaoma. Kushandisa nzira dzemichina kunochenesa chete pamusoro payo uye hakuchinji kuramba ngura kwechinhu chacho pachacho. Saka, zvinokurudzirwa kupukutazve pamusoro nemidziyo yekukwesha uye kuivhara newakisi yekukwesha mushure mekuchenesa nemechanical.

Zvishandiso zvinowanzo shandiswa musimbi isina ngura uye zvivakwa

1.304 simbi isina ngura. Ndiyo imwe yesimbi dzisina ngura dzinoshandiswa zvakanyanya uye dzinoshandiswa zvakanyanya, dzakakodzera kugadzira zvikamu zvekuumba zvakadhonzwa zvakadzama uye mapaipi ane acid, magaba, zvikamu zvechivakwa, mhando dzakasiyana dzemidziyo yemagetsi, nezvimwewo. Inogona zvakare kugadzira michina nezvikamu zvisina magineti, zvinopisa zvishoma.

Simbi isina ngura ye2.304L. Kuti igadzirise kunaya kweCr23C6 kunokonzerwa nesimbi isina ngura ye304 mune mamwe mamiriro ezvinhu, pane katsika kekuora pakati pegranular uye kukura kwesimbi isina ngura ye ultra-low carbon austenitic, mamiriro ayo ekudzivirira ngura pakati pegranular ari nani zvikuru pane simbi isina ngura ye304. Pamusoro pesimba rakaderera zvishoma, zvimwe zvinhu zvine simbi isina ngura ye321, zvinonyanya kushandiswa pakushandisa michina inodzivirira ngura uye zvikamu hazvigone kusungirirwa, zvinogona kushandiswa kugadzira mhando dzakasiyana dzemidziyo.

Simbi isina ngura ye3.304H. Bazi remukati resimbi isina ngura ye304, chikamu chekabhoni chiri mu0.04% ~ 0.10%, kushanda kwekupisa kwakanyanya kuri nani pane simbi isina ngura ye304.

4.316 simbi isina ngura. Musimbi ye10Cr18Ni12 yakavakirwa pakuwedzera kwemolybdenum, kuitira kuti simbi irambe yakasimba pakuderedza ngura uye ngura. Mumvura yegungwa nedzimwe nzira, ngura iri nani pane 304 simbi isina ngura, inonyanya kushandiswa pakugadzira zvinhu zvinodzivirira ngura.

Simbi isina ngura ye5.316L. Simbi ine kabhoni shoma, inodzivirira ngura iri pakati pegranular, yakakodzera kugadzirwa kwezvikamu nemidziyo yakakora, zvakaita semidziyo yepetrochemical muzvinhu zvisingakanganise ngura.

Simbi isina ngura ye6.316H. Bazi remukati resimbi isina ngura ye316, chikamu chekabhoni che0.04%-0.10%, kushanda kwekupisa kwakanyanya kuri nani pane simbi isina ngura ye316.

7.317 simbi isingatsvi. Kudzivirira ngura uye kukwira kwesimbi zviri nani pane 316L simbi isingatsvi, inoshandiswa mukugadzira michina inodzivirira ngura yepetrochemical neorganic acid.

8.321 simbi isina ngura. Simbi isina ngura yakasimbiswa netitanium, ichiwedzera titanium kuti ivandudze ngura pakati pegranular, uye ine hunhu hwakanaka hwemakanika pakupisa kwakanyanya, inogona kutsiviwa nesimbi isina ngura yakakwira-low carbon austenitic. Pamusoro pekudzivirira ngura pakupisa kwakanyanya kana hydrogen nezvimwe zviitiko zvakakosha, mamiriro ezvinhu ese haakurudzirwi.

9.347 simbi isina ngura. Simbi isina ngura yakasimbiswa neNiobium, niobium yakawedzerwa kuti ivandudze kupesana nekuora kwepakati pegranular, kupesana nekuora mu acid, alkali, munyu nezvimwe zvinoparadza ne 321 simbi isina ngura, kushanda zvakanaka kwe welding, inogona kushandiswa sezvinhu zvinodzivirira ngura uye simbi inodzivirira kupisa inoshandiswa zvakanyanya pamagetsi ekupisa, minda ye petrochemical, senge kugadzirwa kwemidziyo, mapaipi, zvinochinja-chinja kupisa, shafts, maindasitiri ekupisa muchubhu yefurnace uye thermometer yechubhu yefurnace nezvimwewo.

Simbi isina ngura ye10.904L. Simbi isina ngura yeaustenitic yakakwana, simbi isina ngura yeaustenitic yakagadzirwa neFinland Otto Kemp, chikamu chayo che nickel mass chiri pakati pe24% kusvika 26%, chikamu checarbon mass chiri pasi pe0.02%, inodzivirira ngura zvakanaka, mumaasidhi asina oxidizing akadai sesulfuric, acetic, formic uye phosphoric acid ine inodzivirira ngura zvakanaka, uye panguva imwe chete ine inodzivirira ngura zvakanaka uye inodzivirira ngura zvakanyanya. Yakakodzera kuwanda kwakasiyana kwesulfuric acid pasi pe70℃, uye ine inodzivirira ngura zvakanaka kune acetic acid uye musanganiswa we formic acid uye acetic acid yechero huwandu uye chero tembiricha pasi pekumanikidzwa kwakajairika. ASMESB-625 yekutanga inoti ine nickel-based alloys, uye chiyero chitsva chinoti ine inodzivirira ngura. China chete inofungidzirwa 015Cr19Ni26Mo5Cu2 simbi, vashoma vagadziri vemidziyo vekuEurope vaishandisa simbi isina ngura ye904L, senge chubhu yekuyera flowmeter yehukuru hweE + H inoshandiswa simbi isina ngura ye904L, bhokisi rewachi reRolex rinoshandiswawo simbi isina ngura ye904L.

11.440C simbi isina ngura. Simbi isina ngura yeMartensitic, simbi isina ngura inoomesesa, simbi isina ngura ine kuoma kwakanyanya, kuomarara HRC57. Inonyanya kushandiswa mukugadzira ma nozzles, ma bearings, ma valve, ma valve spools, ma valve seats, sleeves, ma valve stems, nezvimwewo.

Simbi isina ngura ye12.17-4PH. Simbi isina ngura inoomesa simbi isina ngura ine martensitic precipitation, kuomarara kweHRC44, ine simba rakawanda, kuomarara uye kuramba ngura, haigone kushandiswa pakupisa kunodarika 300 ℃. Inodzivirira ngura zvakanaka kune ese ari mumhepo uye munyu wakaderera, uye kuramba kwayo ngura kwakafanana nekwe304 simbi isina ngura uye 430 simbi isina ngura, iyo inoshandiswa mukugadzira mapuratifomu ekunze, mashizha eturbine, spools, zvigaro, maoko nematsinde emavharuvhu.

Mubasa rekushandisa zvishandiso, pamwe chete nematambudziko emari neakawanda, sarudzo yesimbi isingatsvedzeri inosarudzwa neaustenitic i304-304L-316-316L-317-321-347-904L, iyo 317 isinganyanyi kushandiswa, 321 haikurudzirwi, 347 inoshandiswa pakuora kwakanyanya, 904L ingori chinhu chepakutanga chezvimwe zvikamu zvevagadziri vega vega, dhizaini yacho haizowanzo tora danho rekusarudza 904L.

Mukusarudza magadzirirwo emidziyo, kazhinji pachava nezvinhu zvemidziyo uye zvinhu zvepombi zvakasiyana-siyana, kunyanya mumamiriro ekupisa kwakanyanya, tinofanira kunyatsoteerera kusarudzwa kwezvinhu zvemidziyo kuti zvisangane nemidziyo yekugadzira kana tembiricha yedhizaini yepombi uye kumanikidzwa kwedhizaini, senge pombi yesimbi yechrome molybdenum, nepo midziyo yekusarudza simbi isina ngura, saka zvingangoita kuti pave nedambudziko, unofanira kuenda kunobvunza tembiricha yemidziyo yakakodzera uye gauge yekumanikidza.

Mukusarudza dhizaini yemidziyo, kazhinji panosangana masisitimu akasiyana-siyana, akatevedzana, mamakisi esimbi isina ngura, kusarudzwa kunofanirwa kuenderana nemaitiro chaiwo, tembiricha, kumanikidzwa, zvikamu zvakamanikidzwa, ngura uye mutengo uye mamwe maonero.

Nguva yekutumira: Gumiguru-11-2023