Kurapa kupisa zvinoreva maitiro ekupisa esimbi umo zvinhu zvinopiswa, zvinochengetwa uye zvinotonhodzwa nekupisa muchimiro chakasimba kuitira kuti pave nekurongeka kwaunoda uye hunhu.

I. Kurapa Kupisa

1, Kugadzirisa: zvidimbu zvesimbi kana zvesimbi zvinopiswa kusvika padanho reAC3 kana ACM pamusoro petembiricha yakakodzera kuchengetedza imwe nguva mushure mekutonhorera mumhepo, kuti pave nerudzi rwe pearlitic rwekuronga kwemaitiro ekurapa kupisa.

2, Annealing: workpiece yesimbi inodziya kusvika kuAC3 pamusoro pe20-40 degrees, mushure mekuichengeta kwenguva yakati, choto chichitonhodzwa zvishoma nezvishoma (kana kuvigwa mujecha kana kutonhora kweraimu) kusvika kumadhigirii mazana mashanu pasi pekutonhorera mukupisa kwemhepo.

3, Kurapa kupisa kwemvura ine mhinduro yakasimba: chisanganiswa chinopiswa kusvika munzvimbo ine tembiricha yepamusoro yechikamu chimwe chete chekupisa kwakasimba kuti chirambe chakadaro, kuitira kuti chikamu chakawandisa chinyungudutswe zvizere kuita mhinduro yakasimba, uye chobva chatonhodzwa nekukurumidza kuti chiwane nzira yekurapa kupisa kwemvura ine mhinduro yakasimba yakawandisa.

4、Kukwegura:Mushure mekugadziriswa kwakasimba kwekupisa kana kukanganiswa kwepurasitiki inotonhora ye alloy, kana ikaiswa patembiricha yemukamuri kana kuchengetwa patembiricha yakakwira zvishoma pane tembiricha yemukamuri, chiitiko chehunhu hwayo chinochinja nekufamba kwenguva.

5, Kurapa kwemhinduro yakasimba: kuitira kuti alloy muzvikamu zvakasiyana-siyana inyunguduke zvizere, kusimbisa mhinduro yakasimba uye kuvandudza kusimba uye kuramba ngura, kubvisa kushushikana uye kupfava, kuitira kuti irambe ichigadzirisa kuumbwa.

6, Kurapa kwekukwegura: kupisa uye kubata patembiricha yekunaya kwemvura yechikamu chekusimbisa, kuitira kuti mvura yechikamu chekusimbisa iite mvura, iome, uye iwedzere simba.

7, Kudzima: simbi inotonhorera mushure mekutonhora nekukurumidza kwakakodzera, kuitira kuti workpiece ive isina kugadzikana muchikamu chezvose kana kuti chimiro chesangano chakadai sekuchinja kwemartensite yekurapa kupisa.

8, Kupisa: workpiece yakadzima ichapiswa kusvika padanho reAC1 pasi petembiricha yakakodzera kwenguva yakati, yozotonhodzwa zvichienderana nezvinodiwa nenzira iyi, kuitira kuti pave nekurongeka kwaunoda uye hunhu hwemaitiro ekurapa kupisa.

9, Kugadzira carbonitriding nesimbi: Kugadzira carbonitriding kunosvika pamusoro pesimbi panguva imwe chete kunopinda mu carbonitriding ne nitrogen process. Kugadzira carbonitriding nesimbi inozivikanwawo se cyanide, kugadzira carbonitriding negesi rinopisa uye kugadzira carbonitriding negesi rinopisa (kureva gasi nitrocarburizing) kunonyanya kushandiswa. Chinangwa chikuru chekugadzira carbonitriding nesimbi rinopisa ndechekuvandudza kuomarara, kuramba kupfeka uye simba rekuneta kwesimbi. Kugadzira carbonitriding nesimbi rinopisa zvishoma kubva pakuita nitriding, chinangwa chayo chikuru ndechekuvandudza kuramba kupfeka kwesimbi uye kuramba kuruma.

10, Kugadzirisa (kudzima uye kugadzirisa): tsika yakajairika ichadzimwa uye kudzimwa pakupisa kwakanyanya pamwe chete nekupisa kunozivikanwa sekurapa kupisa. Kugadzirisa kupisa kunoshandiswa zvakanyanya muzvikamu zvakasiyana-siyana zvakakosha zvechivakwa, kunyanya izvo zvinoshanda pasi pematanda akawanda ekubatanidza, mabhaudhi, magiya uye shafts. Kugadzirisa mushure mekugadzirisa kupisa kuti uwane kurongeka kwe sohnite, hunhu hwayo hwemakanika huri nani pane kuoma kwakafanana kwehurongwa hwe sohnite hwakajairwa. Kuoma kwayo kunoenderana nekupisa kwakanyanya uye kugadzikana kwesimbi uye saizi yechikamu chebasa, kazhinji pakati peHB200-350.

11, Brazing: ne brazing material ichave mhando mbiri dze workpiece heating melting yakabatana pamwe chete ne heat treatment process.

II.Thunhu hwemaitiro acho

Kurapa nekupisa nesimbi ndeimwe yenzira dzakakosha mukugadzira michina, zvichienzaniswa nedzimwe nzira dzekugadzira, kurapwa nekupisa kazhinji hakuchinje chimiro chebasa uye makemikari ese, asi nekuchinja magadzirirwo emukati mebasa, kana kushandura magadzirirwo emakemikari pamusoro pebasa, kupa kana kuvandudza mashandisirwo emabasa ebasa. Inoratidzwa nekuvandudzika kwehunhu hwebasa, izvo zvisingawanzoonekwe nemaziso. Kuti basa resimbi riite rine hunhu hwemakanika hunodiwa, hunhu hwepanyama uye hunhu hwemakemikari, kuwedzera pakusarudza zvine musoro kwezvinhu uye maitiro akasiyana-siyana ekuumba, maitiro ekurapa nekupisa anowanzo kuve akakosha. Simbi ndiyo inonyanya kushandiswa muindasitiri yemakanika, simbi microstructure complex, inogona kudzorwa nekupisa, saka kurapwa nekupisa nesimbi ndiyo inonyanya kukosha mukurapa nekupisa nesimbi. Pamusoro pezvo, aruminiyamu, mhangura, magnesium, titanium nedzimwe alloys zvinogonawo kushandiswa nekupisa kuti zvichinje hunhu hwayo hwemakanika, hwepanyama uye hwemakemikari, kuitira kuti pave nekushanda kwakasiyana.

III.Tanoita

Maitiro ekurapa kupisa anowanzo sanganisira kupisa, kubata, kutonhodza maitiro matatu, dzimwe nguva kupisa nekutonhodza maitiro maviri chete. Maitiro aya akabatana, haagoni kukanganiswa.

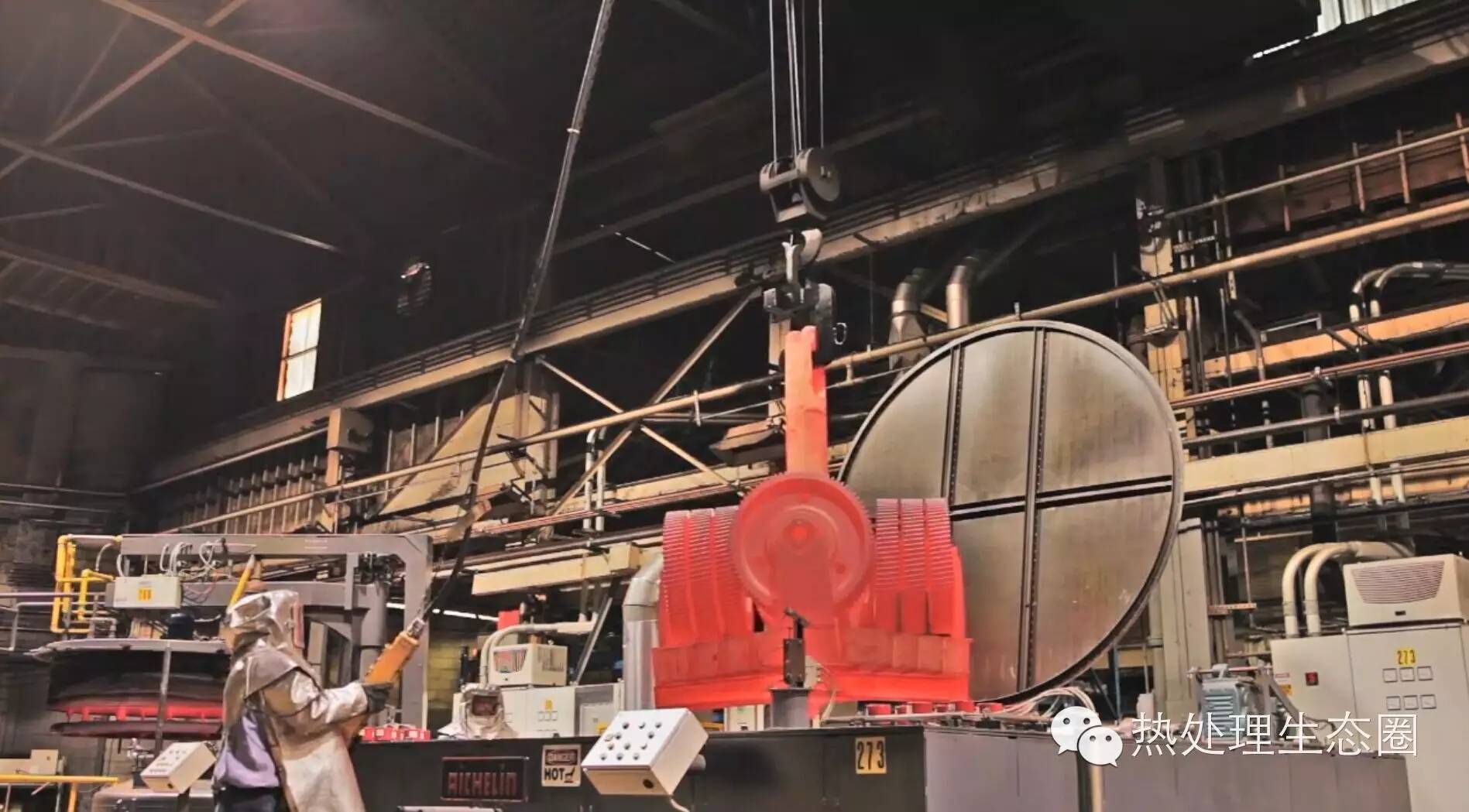

Kupisa ndeimwe yenzira dzakakosha dzekurapa kupisa. Kupisa nesimbi nenzira dzakawanda dzekupisa, yekutanga kushandisa marasha nemarasha senzvimbo yekupisa, kushandiswa kwemafuta emvura negasi munguva pfupi yapfuura. Kushandiswa kwemagetsi kunoita kuti kupisa kuve nyore kudzora, uye kusasvibisa nharaunda. Kushandiswa kwezvitubu izvi zvekupisa kunogona kupiswa zvakananga, asiwo kuburikidza nemunyu wakanyungudutswa kana simbi, kusvika kune zvidimbu zvinoyangarara kuti zvipiswe zvisina kunanga.

Kupisa kwesimbi, workpiece inobatwa nemhepo, oxidation, decarburization inowanzoitika (kureva, huwandu hwekabhoni hwezvikamu zvesimbi hunoderedza), izvo zvine mhedzisiro yakaipa kwazvo pahunhu hwezvikamu zvakagadziriswa kupisa. Saka, simbi inowanzo kuve mumhepo inodzorwa kana mhepo inodzivirira, munyu wakanyungudutswa uye kupisa kwevacuum, asiwo machira kana nzira dzekurongedza dzinowanikwa dzekudzivirira kupisa.

Kupisa kupisa ndeimwe yenzira dzakakosha dzekugadzirisa kupisa, kusarudzwa nekudzorwa kwekupisa, ndiko kuve nechokwadi chekuti zvinhu zvikuru zviri kubatwa zvakanaka. Kupisa kupisa kunosiyana zvichienderana nesimbi yakarapwa uye chinangwa chekupisa, asi kazhinji kunopiswa pamusoro pekupisa kwechikamu kuti kugadzirwe kupisa kwakanyanya. Pamusoro pezvo, kushandurwa kunoda nguva yakati, saka kana pamusoro pesimbi workpiece painosvika tembiricha yekupisa inodiwa, inofanirawo kuchengetedzwa pakupisa uku kwenguva yakati, kuitira kuti tembiricha yemukati neyekunze ienderane, kuitira kuti kushanduka kwe microstructure kupere, iyo inozivikanwa senguva yekubata. Kushandisa kupisa kwesimba rakawanda uye kupisa kwepamusoro, mwero wekupisa unokurumidza zvikuru, kazhinji hapana nguva yekubata, nepo kurapa kupisa kwemakemikari kwenguva yekubata kazhinji kwakareba.

Kutonhodza inhanho inokosha mukurapa kupisa, nzira dzekutonhodza dzinoshandiswa nenzira dzakasiyana, kunyanya kudzora mwero wekutonhodza. Mwero wekutonhodza weGeneral annealing ndiwo unononoka, kunonotsa mwero wekutonhodza nekukurumidza, kunonotsa mwero wekutonhodza nekukurumidza. Asi zvakare nekuda kwemhando dzakasiyana dzesimbi uye dzine zvinodiwa zvakasiyana, senge simbi yakaomeswa nemhepo inogona kudzimwa nemwero wekutonhodza wakafanana newekunonotsa.

IV.Pkurongwa kwehurongwa

Maitiro ekurapa kupisa kwesimbi anogona kukamurwa muzvikamu zvitatu zvekurapa kupisa kwese, kurapwa kwekupisa pamusoro uye kurapwa kwekupisa kwemakemikari. Zvichienderana nekupisa kwepakati, tembiricha yekupisa uye nzira yekutonhodza yemhando dzakasiyana, chikamu chimwe nechimwe chinogona kusiyaniswa mumatanho akasiyana ekurapa kupisa. Simbi imwecheteyo ichishandisa maitiro akasiyana ekurapa kupisa, inogona kuwana masangano akasiyana, nokudaro iine hunhu hwakasiyana. Simbi nesimbi ndiyo simbi inonyanya kushandiswa muindasitiri, uye simbi microstructure ndiyo yakaomawo, saka kune maitiro akasiyana-siyana ekurapa kupisa kwesimbi.

Kurapa kupisa kwakazara ndiko kupisa kwechinhu chebasa, uye kwozotonhodzwa nechiyero chakakodzera, kuti pave nekurongeka kwesimbi kunodiwa, kuitira kuti ichinje hunhu hwayo hwese hwekugadzirisa kupisa kwesimbi. Kurapa kupisa kwakazara kwesimbi kunowedzera, kunogadzirisa, kudzima uye kudzikamisa maitiro mana ekutanga.

Maitiro anoreva:

Annealing ibasa rinodziiswa kusvika patembiricha yakakodzera, zvichienderana nezvinhu uye saizi yebasa uchishandisa nguva yakasiyana yekubata, uye wozotonhodzwa zvishoma nezvishoma, chinangwa ndechekuita kuti sangano remukati resimbi risvike kana pedyo nemamiriro ekuenzanisa, kuti riwane mashandiro akanaka ekuita uye kushanda, kana kuti riwedzere kudzimwa kwesangano rekugadzirira.

Kugadzirisa zvinoreva kuti workpiece inodziiswa kusvika patembiricha yakakodzera mushure mekutonhorera mumhepo, mhedzisiro yekururamisa yakafanana ne annealing, asi kuti iwane sangano rakanaka, rinowanzoshandiswa kuvandudza mashandiro ekucheka kwezvinhu, asi dzimwe nguva rinoshandiswawo kune zvimwe zvikamu zvisinganyanyi kuoma sekurapa kwekupedzisira kwekupisa.

Kudzima ndiko kunodziiswa uye kunodzivirira, mumvura, mafuta kana mimwe munyu isingasanganisike, mhinduro dzemvura dzinobva muorganic uye imwe nzira yekudzima kuti itonhore nekukurumidza. Mushure mekudzima, zvikamu zvesimbi zvinova zvakaoma, asi panguva imwe chete zvinova zvakaoma, kuti kubvisa kusimba panguva yakakodzera, zvinowanzodiwa kuti zviome panguva yakakodzera.

Kuti zvideredze kuputsika kwezvikamu zvesimbi, zvikamu zvesimbi zvakadzimwa patembiricha yakakodzera kupfuura tembiricha yemumba uye pasi pe650 ℃ kwenguva yakareba yekuputira, uye zvozotonhodzwa, maitiro aya anonzi tempering. Annealing, normalizing, quenching, tempering ndiyo nzira yekurapa kupisa mu "moto mina", iyo quenching ne tempering zvakabatana, kazhinji zvinoshandiswa pamwe chete, imwe inokosha. "Moto mina" ine tembiricha yekupisa uye kutonhora kwakasiyana, uye yakagadzira nzira yakasiyana yekurapa kupisa. Kuti uwane simba rakati uye kusimba, quenching ne tempering patembiricha dzakakwirira zvinosanganiswa nemaitiro, anozivikanwa se tempering. Mushure mekunge mamwe ma alloys adzimwa kuti aumbe mhinduro yakasimba, anochengetwa patembiricha yemumba kana patembiricha yakakwira zvishoma yakakodzera kwenguva yakareba kuitira kuvandudza kuoma, simba, kana magnetism yemagetsi ye alloy. Maitiro akadaro ekurapa kupisa anonzi treatment age.

Kugadziriswa kwekugadzirisa kudzvanywa uye kurapwa kwekupisa zvinobudirira uye zvakabatana kuti zviitwe, kuitira kuti workpiece iwane simba rakanaka, kusimba nenzira inozivikanwa se deformation heat treatment; mumhepo ine kumanikidzwa kwakashata kana vacuum mukupisa kunozivikanwa se vacuum heat treatment, iyo isingangogone chete kuita kuti workpiece isaoxidize, isabvisa carburize, ichengetedze pamusoro peworkpiece mushure mekurapa, inovandudza mashandiro eworkpiece, asiwo kuburikidza ne osmotic agent yekurapa kupisa kwemakemikari.

Kurapa kupisa pamusoro pechinhu kunongodziisa pamusoro pechinhu chebasa kuti kuchinje hunhu hwechigadzirwa chepamusoro pechinhu chesimbi. Kuti chidziise chete chikamu chepamusoro chechinhu chebasa pasina kutamiswa zvakanyanya kwekupisa muchinhu chebasa, kushandiswa kwechinhu chekupisa kunofanirwa kuve nesimba rakawanda, kureva kuti, munzvimbo yechikamu chechinhu chebasa kuti chipe simba guru rekupisa, kuitira kuti chikamu chepamusoro chechinhu chebasa kana chakaiswa munzvimbo yacho chigone kuva kwenguva pfupi kana nekukurumidza kusvika pakupisa kwakanyanya. Kurapa kupisa pamusoro pechinhu chebasa nenzira huru dzekudzima moto uye kurapwa kwekupisa kwekudzimisa moto, masosi ekupisa anoshandiswa zvakanyanya akadai seoxyacetylene kana oxypropane flame, induction current, laser uye electron beam.

Kurapa kupisa kwemakemikari inzira yekurapa kupisa kwesimbi nekuchinja maumbirwo emakemikari, kurongeka uye hunhu hwepamusoro pechikamu chebasa. Kurapa kupisa kwemakemikari kwakasiyana nekurapa kupisa kwepamusoro nekuti yekutanga inoshandura maumbirwo emakemikari echikamu chebasa. Kurapa kupisa kwemakemikari kunoiswa pachikamu chebasa chine kabhoni, munyu kana zvimwe zvinhu zve alloying zvepakati (gasi, mvura, solid) mukupisa, insulation kwenguva yakareba, kuitira kuti chikamu chepamusoro chechikamu chebasa chipinde mucarbon, nitrogen, boron uye chromium nezvimwe zvinhu. Mushure mekupinzwa kwezvinhu, uye dzimwe nguva mamwe maitiro ekurapa kupisa akadai sekudzima uye tempering. Nzira huru dzekurapa kupisa kwemakemikari ndeye carburizing, nitriding, kupinda kwesimbi.

Kurapa kupisa ndeimwe yenzira dzakakosha mukugadzirwa kwezvikamu zvemakanika uye molds. Kazhinji, zvinogona kuve nechokwadi nekuvandudza hunhu hwakasiyana hwebasa, senge kuramba kupfeka, kuramba ngura. Zvinogona zvakare kuvandudza kurongeka kwenzvimbo isina chinhu uye mamiriro ekushushikana, kuitira kuti zvive nyore kugadzira zvinhu zvakasiyana-siyana zvinotonhora uye zvinopisa.

Semuenzaniso: simbi chena yakakandwa mushure menguva yakareba yekurapa annealing inogona kuwanikwa simbi yakakandwa inonyungudika, kuvandudza plasticity; magiya ane maitiro akakodzera ekurapa kupisa, hupenyu hwebasa hunogona kuva hwakawanda kupfuura kwete magiya anorapwa kupisa kanopfuura kagumi kana kakawanda; pamusoro pezvo, simbi yekabhoni isingadhuri kuburikidza nekupinda kwezvimwe zvinhu zvekusanganisa ine mashandiro esimbi anodhura, inogona kutsiva simbi isingapisi, simbi isingapisi; mapundu nemadheya zvinenge zvese zvinodiwa kuti zvipfuure nekupisa. Inogona kushandiswa chete mushure mekupisa.

Zvimwe zvinoreva

I. Mhando dze annealing

Annealing inzira yekurapa kupisa umo workpiece inodziiswa kusvika patembiricha yakakodzera, inochengetwa kwenguva yakati, yozotonhodzwa zvishoma nezvishoma.

Kune mhando dzakawanda dzesimbi dzinoshandiswa pakupinza simbi, zvichienderana nekupisa tembiricha, inogona kukamurwa kuita zvikamu zviviri: imwe iri pakupisa kwakakosha (Ac1 kana Ac3) pamusoro pe annealing, inozivikanwawo se phase change recrystallization annealing, kusanganisira complete annealing, incomplete annealing, spheroidal annealing uye diffusion annealing (homogenization annealing), nezvimwewo; imwe iri pasi pekupisa kwakakosha kwe annealing, kusanganisira recrystallization annealing uye de-stressing annealing, nezvimwewo. Zvichienderana nenzira yekutonhodza, annealing inogona kukamurwa kuita isothermal annealing uye continuous cooling annealing.

1, kunyungudutsa kwakakwana uye kunyungudutsa kwe isothermal

Kubatanidza kwakazara, kunozivikanwawo se recrystallization annealing, kunowanzozivikanwa se annealing, isimbi kana simbi inopisirwa kuAc3 pamusoro pe20 ~ 30 ℃, insulation yakareba zvakakwana kuti sangano rive austenitized zvizere mushure mekutonhora zvishoma nezvishoma, kuitira kuti pave nehurongwa hwakafanana hwekugadzirisa kupisa. Kubatanidza uku kunonyanya kushandiswa mukugadzirwa kwe sub-eutectic kwesimbi dzakasiyana-siyana dzekabhoni ne alloy, forgings uye hot-rolled profiles, uye dzimwe nguva kunoshandiswawo kune zvivakwa zvakasungirirwa. Kazhinji kazhinji senzira yekurapa kupisa yekupedzisira isina kurema, kana senzira yekurapa kwemamwe mativi ebasa asati apisa.

2, bhora rinonamira

Kunyungudutsa kwesimbi kunonyanya kushandiswa pakugadzira simbi ine kabhoni yakawanda uye simbi yesimbi ine alloy (yakadai sekugadzira maturusi ane edges, gauges, molds uye madies anoshandiswa musimbi). Chinangwa chayo chikuru ndechekuderedza kuomarara kwayo, kuvandudza mashandiro ayo, uye kugadzirira kudzimwa kwayo mune ramangwana.

3, kubvisa kushushikana

Kudzikisa kushushikana, kunozivikanwawo sekudzikisa kunopisa zvakanyanya (kana kudzikisa kupisa kwakanyanya), kudzikisa uku kunonyanya kushandiswa kubvisa kukanda, kupinza, kuchinjika, zvikamu zvinopisa, zvikamu zvinodhonzwa nechando nezvimwe zvinosara. Kana kumanikidzwa uku kukasabviswa, kunokonzera simbi mushure menguva yakati, kana kuti mukuita kwekucheka kunotevera kunokonzera kutsemuka kana kupwanyika.

4. Kupisa simbi kusina kukwana kunosanganisira kupisa simbi kusvika kuAc1 ~ Ac3 (sub-eutectic steel) kana kuti Ac1 ~ ACcm (over-eutectic steel) pakati pekuchengetedza kupisa nekutonhodza zvishoma nezvishoma kuti pave nekurongeka kwakaringana kwemaitiro ekurapa kupisa.

II.kudzima, chinhu chinonyanya kushandiswa pakutonhodza imvura ine munyu, mvura nemafuta.

Kudzima mvura ine munyu pabasa, kuri nyore kuwana kuomarara kwakanyanya uye pamusoro payo pakapfava, hazvisi nyore kudzima kwete nzvimbo yakaoma yakapfava, asi zviri nyore kuita kuti basa rive rakakomba, uye rinototsemuka. Kushandisa mafuta senzira yekudzima kunongokodzera chete kugadzikana kwe supercooled austenite yakakura musimbi ye alloy kana diki diki ye carbon steel workpiece quenching.

III.chinangwa chekupisa simbi

1, kuderedza kuputsika, kubvisa kana kuderedza kushushikana kwemukati, kudzima simbi kune kushushikana kukuru kwemukati uye kuputsika, sekunge kusagadziriswa nenguva kunowanzoita kuti simbi ishanduke kana kutotsemuka.

2, kuti uwane hunhu hwemakanika hunodiwa hwebasa, basa racho mushure mekudzima kuomarara kwakanyanya uye kuputsika, kuitira kuti ugone kusangana nezvinodiwa zvehunhu hwakasiyana hwebasa rakasiyana-siyana, unogona kugadzirisa kuomarara kuburikidza nekupisa kwakakodzera kuderedza kuputsika kwekusimba kunodiwa, plasticity.

3. Gadzirisa saizi yechinhu chebasa

4, kune mamwe simbi dzesimbi dzakaoma kupfavisa, dzimwe simbi dzesimbi dzinodzima (kana kuti dzinogadzirisa) dzinowanzoshandiswa mushure mekudzimisa tembiricha yepamusoro, kuitira kuti simbi iunganidzwe zvakanaka, kuomarara kuchaderedzwa, kuitira kuti zvive nyore kucheka nekugadzirisa.

Pfungwa dzekuwedzera

1, annealing: zvinoreva zvinhu zvesimbi zvinopiswa kusvika patembiricha yakakodzera, zvinochengetwa kwenguva yakati, uye zvozotonhodzwa zvishoma nezvishoma. Maitiro akajairika e annealing ndeaya: recrystallization annealing, stress relief annealing, spheroidal annealing, complete annealing, nezvimwewo. Chinangwa che annealing: kunyanya kuderedza kuomarara kwezvinhu zvesimbi, kuvandudza plasticity, kuitira kuti zvive nyore kucheka kana kugadzira pressure, kuderedza kushushikana kwasara, kuvandudza kurongeka uye kuumbwa kwe homogenization, kana kuti kurapwa kwekupedzisira kwekupisa kuti sangano rigadzirire.

2, kugadzirisa: zvinoreva simbi kana simbi inopisa kana (simbi iri panzvimbo yakakosha yekupisa) pamusoro, 30 ~ 50 ℃ kuchengetedza nguva yakakodzera, kutonhora mumhepo isina kusimba. Chinangwa chekugadzirisa: kunyanya kuvandudza hunhu hwesimbi ine kabhoni shoma, kuvandudza kucheka uye mashandiro, kunatsiridza tsanga, kubvisa zvikanganiso zvesangano, kuti kurapwa kwekupisa kwekupedzisira kugadzirire sangano.

3, kudzima: zvinoreva simbi inopisa kuAc3 kana Ac1 (simbi iri pasi penzvimbo yakakosha yekupisa) pamusoro peimwe tembiricha, inochengetedza nguva yakati, uye yozosvika pakutonhora kwakakodzera, kuti iwane martensite (kana bainite) kuronga kwemaitiro ekurapa kupisa. Maitiro akajairika ekudzima ndeekudzima kwepakati nepakati, kudzima kwepakati nepakati, kudzima kwemartensite, kudzima kweisothermal kwebainite, kudzima pamusoro uye kudzima kwenzvimbo. Chinangwa chekudzima: kuitira kuti zvikamu zvesimbi zviwane kurongeka kwemartensitic kunodiwa, kuvandudza kuoma kwebasa, simba uye kuramba kwekukwesha, kuitira kuti kurapwa kwekupisa kwekupedzisira kugadzirire zvakanaka sangano.

4, kudziya: zvinoreva simbi yakaomeswa, yozodziiswa kusvika patembiricha iri pasi peAc1, ichibata nguva, yozotonhodzwa kusvika patembiricha yemukamuri. Maitiro akajairika ekudziya ndeaya: kudziyisa patembiricha yakaderera, kudziyisa patembiricha iri pakati nepakati, kudziyisa patembiricha yepamusoro uye kudziyisa kakawanda.

Chinangwa chekugadzirisa: chinonyanya kubvisa kushushikana kunokonzerwa nesimbi iri mukudzimisa, kuitira kuti simbi ive nekuomarara kwakanyanya uye irambe ichiramba kupfeka, uye ive nepurasitiki uye kusimba kunodiwa.

5, tempering: zvinoreva simbi kana simbi yekudzima uye tempering yepamusoro-soro yemaitiro ekugadzirisa kupisa kwakabatana. Inoshandiswa mukugadzirisa simbi inonzi tempering steel. Inowanzoreva simbi yekuvaka ine kabhoni yepakati nepakati uye simbi yekuvaka ine kabhoni yepakati.

6, carburizing: carburizing inzira yekuita kuti maatomu ekabhoni apinde muchikamu chepamusoro chesimbi. Zvakare kugadzira chikamu chesimbi chine kabhoni shoma chine chikamu chepamusoro chesimbi ine kabhoni yakawanda, uye mushure mekudzima uye kupisa tembiricha yakaderera, kuitira kuti chikamu chepamusoro chechinhu chacho chive chakaoma uye chinodzivirira kupfeka, nepo chikamu chepakati chechinhu chacho chichiri kuchengetedza kusimba uye purasitiki kwesimbi ine kabhoni shoma.

Nzira yekubvisa vharuvhu

Nekuti mashandiro ekupisa nekutonhodza esimbi anoda mabasa gumi nemaviri kana kunyange makumi maviri kuti apedziswe. Mabasa aya anoitwa mukati mechoto chekupisa chevacuum, mushandi haakwanise kusvika, saka mwero wekuzvigadzira wega wechoto chekupisa chevacuum unofanirwa kunge wakakwira. Panguva imwe chete, mamwe mabasa, akadai sekupisa nekubata mugumo wemaitiro ekudzima simbi anofanira kunge ari matanhatu, manomwe uye anofanira kupedzwa mukati memasekonzi gumi nemashanu. Mamiriro ezvinhu akadaro ekumhanya-mhanya kuti apedze mabasa mazhinji, zviri nyore kukonzera kutya kwemushandi uye kuita kusashanda zvakanaka. Naizvozvo, mwero wepamusoro wekuzvigadzira wega chete ndiwo unogona kuva nehurongwa hwakarurama, hunoenderana nenguva.

Kurapa zvikamu zvesimbi nekupisa kwevacuum kunoitwa muchoto chevacuum chakavharwa, kuvharwa kwevacuum kwakasimba kunozivikanwa. Saka, kuti uwane uye utevedzere mwero wekutanga wekubuda kwemhepo muchoto, kuve nechokwadi chekuti vacuum inoshanda muchoto chevacuum, kuve nechokwadi chekuti mhando yezvikamu zvekupisa kwevacuum kune kukosha kukuru. Saka nyaya huru yechoto chevacuum heat treatment ndeyekuva nechimiro chevacuum sealing chakavimbika. Kuti ive nechokwadi chekuti vacuum furnace inoshanda zvakanaka, dhizaini yechivako chevacuum heat treatment inofanira kutevedzera musimboti wekutanga, kureva kuti, muviri wechoto unofanira kushandisa welding isina gasi, nepo muviri wechoto usingavhuri gomba zvakanyanya sezvinobvira, kuderedza kana kudzivirira kushandiswa kwechimiro chekusimbisa chinoshanduka, kuitira kuderedza mukana wekubuda kwevacuum. Zvikamu zvemuviri wechoto chevacuum, zvishandiso, zvakaita semaelectrode anotonhorerwa nemvura, mudziyo wekutumira kunze wethermocouple unofanirwawo kugadzirwa kuti uvhare chimiro.

Zvizhinji zvezvinhu zvinodziya uye zvinodzivirira zvinogona kushandiswa chete pasi pevacuum. Kupisa nekupisa muchoto chevacuum uye thermal insulation lining zviri muvacuum uye kushanda kwekupisa kwakanyanya, saka zvinhu izvi zvinopa simba rekudzivirira kupisa kwakanyanya, mhedzisiro yemwaranzi, conductivity yekupisa nezvimwe zvinodiwa. Zvinodiwa zvekudzivirira oxidation hazvisi zvepamusoro. Naizvozvo, vacuum heat treatment furnace inoshandiswa zvakanyanya tantalum, tungsten, molybdenum uye graphite pakudziyisa nekupisa zvinhu. Zvinhu izvi zviri nyore kwazvo kuoxidation mumamiriro ekunze, saka, wakajairika heat treatment furnace haigone kushandisa zvinhu izvi zvekudziyisa nekudzivirira.

Mudziyo unotonhodzwa nemvura: goko rechoto chekupisa chevacuum, chifukidziro chechoto, zvinhu zvinodziya zvemagetsi, maerekitironi anotonhodzwa nemvura, gonhi repakati rekudzivirira kupisa kwevacuum nezvimwe zvinhu, zviri muvacuum, pasi pemamiriro ekupisa. Kushanda mumamiriro ezvinhu asina kunaka kudaro, kunofanirwa kuve nechokwadi chekuti chimiro chechikamu chimwe nechimwe hachina kukanganiswa kana kukuvara, uye chisimbiso chevacuum hachina kupiswa zvakanyanya kana kupiswa. Naizvozvo, chikamu chimwe nechimwe chinofanira kugadzirwa zvichienderana nemamiriro akasiyana-siyana michina yekutonhodza mvura kuti ive nechokwadi chekuti choto chekurapa kupisa chevacuum chinogona kushanda zvakanaka uye chive nehupenyu hwakakwana hwekushandisa.

Kushandisa mudziyo wevacuum une voltage yakaderera, kana vacuum vacuum iri padanho re lxlo-1 torr, mudziyo wevacuum wemuchina une simba uri pa voltage yakakwira, uchaburitsa chiedza. Muchoto chekurapa kupisa chevacuum, chiedza chakakomba che arc chichapisa chinhu chekupisa chemagetsi, insulation layer, zvichikonzera tsaona huru nekurasikirwa. Nokudaro, chiedza chemagetsi chekupisa che vacuum hachipfuuri 80 kusvika 100 volts. Panguva imwe chete, matanho anoshanda mukugadzira chimiro chemagetsi chekupisa, akadai sekuedza kudzivirira magumo ezvikamu, electrode spacing pakati pe electrodes haigone kuve diki zvakanyanya, kuitira kudzivirira kugadzirwa kwechiedza kana arc discharge.

Kudzikisa

Zvichienderana nezvinodiwa zvakasiyana zvekushanda kwechinhu chebasa, zvichienderana nekupisa kwaro kwakasiyana, zvinogona kukamurwa kuita mhando dzinotevera dzekupisa:

(a) kudziya kwekupisa kushoma (150-250 degrees)

Kudziisa tembiricha yakaderera yesangano rinobuda remartensite yakapfava. Chinangwa chayo ndechekuchengetedza kuomarara kwakanyanya uye kuramba kwakanyanya kwesimbi yakadzima nekuda kwekuderedza kushushikana kwayo kwemukati uye kuputsika, kuitira kudzivirira kupwanyika kana kukuvara nguva isati yakwana panguva yekushandiswa. Inonyanya kushandiswa kune akasiyana maturusi ekucheka ane kabhoni yakawanda, magauge, madhiri anodhonzwa nechando, mabheyaringi anotenderera uye zvikamu zvekabhoni, nezvimwewo, mushure mekudziisa kuomarara kunowanzoitwa HRC58-64.

(ii) kudziya tembiricha iri pakati nepakati (250-500 degrees)

Kurongeka kwekudziya kwepakati nepakati kwemuviri we quartz inodziya. Chinangwa chayo ndechekuwana simba rekugadzira, muganho we elastic uye kusimba kwakanyanya. Saka, inonyanya kushandiswa kune akasiyana-siyana masprings uye hot work mold processing, kuomarara kwekudziya kunowanzova HRC35-50.

(C) kudziya tembiricha yepamusoro (500-650 degrees)

Kudziisa tembiricha yepamusoro kwesangano reSohnite inodziya. Kudziisa tembiricha yepamusoro uye kudziisa tembiricha yepamusoro kunosanganisira kurapwa kwekupisa kunozivikanwa sekudziisa tembiricha, chinangwa chayo ndechekuwana simba, kuomarara uye plasticity, kuomarara kuri nani muzvinhu zvemakanika. Saka, inoshandiswa zvakanyanya mumotokari, matrakita, maturusi emuchina nezvimwe zvikamu zvakakosha zvechimiro, zvakaita sematanda ekubatanidza, mabhaudhi, magiya uye shafts. Kuomarara mushure mekudziisa tembiricha kunowanzova HB200-330.

Kudzivirira kuchinja kwechimiro

Zvikonzero zvekusanduka kwechinhu chakakombama zvine hungwaru zvinowanzova zvakaoma, asi tinongoziva mutemo wekusanduka kwacho, tinoongorora zvikonzero zvacho, tichishandisa nzira dzakasiyana dzekudzivirira kusanduka kwechinhu chakakombama, tinokwanisa kuderedza, asi zvakare kudzora. Kazhinji, kurapwa nekupisa kwekusanduka kwechinhu chakakombama zvine hungwaru kunogona kutora nzira dzinotevera dzekudzivirira.

(1) Kusarudzwa kwezvinhu zvine musoro. Zviumbwa zvakaoma zvinofanira kusarudzwa nesimbi yakanaka ye microdeformation (yakadai sesimbi inodzima mweya), kupatsanurwa kwesimbi ye mold ne carbide kunofanira kunge kwakanyatsogadzirwa uye kuchipisa, uye simbi ye mold yakakura uye isingagone kuumbwa inogona kunge yakasimba.

(2) Dhizaini yechivako chevhu inofanira kunge yakaringana, ukobvu hwayo husanyanye kusiyana, chimiro chayo chinofanira kunge chakaenzana, kuti vhunduko revhu guru rigone kutevedzera mutemo wevhunduko, mvumo yekugadzirisa yakachengeterwa, kuti vhundu hombe, dzakanyatsojeka uye dzakaoma dzishandiswe mukubatanidzwa kwezvivako.

(3) Makuvhuru akanyatsogadzirwa uye akaomarara anofanira kushandiswa pakupisa kuti abvise kushushikana kunokonzerwa nekugadzirwa kwemuchina.

(4) Kusarudza tembiricha yekupisa zvine musoro, dzora kumhanya kwekupisa, kuti zvive nemazvo, maforoma akaomarara anogona kutora kupisa kunononoka, kupisa kwekutanga uye dzimwe nzira dzakaringana dzekupisa kuderedza kushanduka kwekupisa kweforoma.

(5) Pasi pepfungwa yekuona kuoma kwechiumbwa, edza kushandisa nzira yekutonhodza isati yatanga, yekudzima kutonhora yakarongwa kana yekudzima tembiricha.

(6) Kuti muwane maforoma akanyatsonaka uye akaomarara, kana mamiriro ezvinhu achibvumira, edzai kushandisa vacuum heating quenching uye deep cooling treatment mushure mekudzima.

(7) Kuti uwane mamwe maforoma akanyatsojeka uye akaomarara, unogona kushandisa pre-heat treatment, kuchembera kupisa, tempering nitriding heat treatment kudzora kururama kweforoma.

(8) Mukugadzirisa maburi ejecha remuforoma, maburi, kupfekwa nezvimwe zvikanganiso, kushandiswa kwemuchina wekunamira unotonhora pamwe nekumwe kupisa kwemidziyo yekugadzirisa kudzivirira maitiro ekugadzirisa ekushanduka-shanduka.

Pamusoro pezvo, mashandiro akakodzera ekugadzirisa kupisa (akadai sekuvhara maburi, maburi akasungwa, kugadzirisa michina, nzira dzakakodzera dzekupisa, sarudzo chaiyo yenzira yekutonhodza yemould uye gwara rekufamba munzvimbo inotonhodza, nezvimwewo) uye maitiro ekugadzirisa kupisa zvine mwero ndeekuderedza kuchinjika kwekuita kwakarurama uye mafungu akaomarara zvakare matanho anoshanda.

Kudzima pamusoro uye tempering heat treatment kunowanzoitwa ne induction heating kana moto. Zvinhu zvikuru zvehunyanzvi ndezvekuoma kwenzvimbo, kuoma kwenzvimbo uye kudzika kwe effective hardening layer. Kuedza kuoma kunogona kushandiswa Vickers hardness tester, kunogonawo kushandiswa Rockwell kana surface Rockwell hardness tester. Sarudzo ye test force (scale) ine chekuita nekudzika kwe effective hardening layer uye kuoma kwe surface workpiece. Mhando nhatu dze hardness testers dzinobatanidzwa pano.

Chekutanga, Vickers hardness tester inzira yakakosha yekuedza kuomarara kwepamusoro kwezvishandiso zvebasa zvakagadziriswa kupisa, inogona kusarudzwa kubva pa 0.5 kusvika 100kg yesimba rekuyedza, kuyedza ganda rekuomesa repamusoro rakatetepa se 0.05mm ukobvu, uye kururama kwaro ndiko kwakanyanya, uye inogona kusiyanisa misiyano midiki mukuomarara kwepamusoro kwezvishandiso zvakagadziriswa kupisa. Pamusoro pezvo, kudzika kweganda rakaomeswa kunoshanda kunofanirawo kuonekwa neVickers hardness tester, saka pakugadzirisa kupisa kwepamusoro kana huwandu hwakawanda hwezvishandiso zvinoshandisa workpiece yekurapa kupisa kwepamusoro, ine Vickers hardness tester inodiwa.

Chechipiri, muyedzi wekusimbisa kuomarara wepamusoro weRockwell wakakodzerawo kuyedza kuomarara kwechinhu chakaomeswa pamusoro, muyedzi wekusimbisa kuomarara wepamusoro weRockwell une zviyero zvitatu zvekusarudza kubva. Unogona kuyedza kudzika kwekusimbisa kwakanaka kweanopfuura 0.1mm echinhu chakasiyana-siyana chekusimbisa kuomarara kwepamusoro. Kunyangwe kunyatsojeka kwemuyedzi wekusimbisa kuomarara wepamusoro weRockwell kusina kukwira semuyedzi wekusimbisa kuomarara weVickers, asi semuyedzi wekupisa wekutarisira mhando uye nzira dzekuongorora dzakanyatsokodzera, yakakwanisa kusangana nezvinodiwa. Uyezve, inewo mashandiro ari nyore, ari nyore kushandisa, mutengo wakaderera, kuyerwa nekukurumidza, inogona kuverenga zvakananga kukosha kwekuomarara nezvimwe hunhu, kushandiswa kwemuyedzi wekusimbisa kuomarara weRockwell kunogona kuva batch yemuyedzi wekusimbisa kupisa kwepamusoro wekuyedza nekukurumidza uye kusingaparadze chidimbu nechidimbu. Izvi zvakakosha kune simbi yekugadzira michina nekugadzira michina.

Chechitatu, kana pamusoro pekupisa kwakaomarara layer yakakora, inogona zvakare kushandiswa Rockwell hardness tester. Kana kupisa kwakasimbara layer yakakora 0.4 ~ 0.8mm, inogona kushandiswa HRA scale, kana yakasimbara layer yakakora kupfuura 0.8mm, inogona kushandiswa HRC scale.

Vickers, Rockwell uye Rockwell pamusoro pemhando nhatu dzehukukutu dzinogona kushandurwa zviri nyore, kushandurwa kuita standard, mifananidzo kana mushandisi achida hukukutu. Matafura ekushandura anoenderana anopiwa mu standard yepasi rose yeISO, American standard ASTM uye Chinese standard GB/T.

Kuomesa kwenzvimbo

Zvikamu kana zvinodiwa zvekuoma kwenzvimbo yenzvimbo yekupisa kwepamusoro, kunowanikwa kwekudziisa uye dzimwe nzira dzekurapa kupisa kwenzvimbo yenzvimbo yekudziisa, zvikamu zvakadaro zvinowanzo fanirwa kuratidza nzvimbo yekurapa kupisa kwenzvimbo yekudziisa uye kukosha kwekuoma kwenzvimbo pamifananidzo. Kuyedzwa kwekuoma kwezvikamu kunofanirwa kuitwa munzvimbo yakatarwa. Zvishandiso zvekuedza kuoma zvinogona kushandiswa Rockwell hardness tester, test HRC hardness value, senge heat treatment hardening layer isina kudzika, inogona kushandiswa pamusoro Rockwell hardness tester, test HRN hardness value.

Kurapa kupisa kwemakemikari

Kurapa kupisa kwemakemikari kunosanganisira kuita kuti pamusoro pechinhu chebasa papinde chimwe kana zvimwe zvinhu zvemakemikari zvemaatomu, kuitira kuti pashandurwe kuumbwa kwemakemikari, kurongeka uye mashandiro epamusoro pechinhu chebasa. Mushure mekudzima uye kudziya tembiricha yakaderera, pamusoro pechinhu chebasa pachava nekuomarara kwakanyanya, kuramba kupfeka uye simba rekuneta, nepo pakati pechinhu chebasa pakava nekuomarara kwakanyanya.

Zvichienderana nezviri pamusoro apa, kuona nekurekodha tembiricha mukurapa kupisa kwakakosha zvikuru, uye kudzora tembiricha kwakashata kune simba guru pachigadzirwa. Saka, kuona tembiricha kwakakosha zvikuru, mafambiro etembiricha mukuita kwese kwakakoshawo zvikuru, zvichiita kuti maitiro ekurapa kupisa anyorerwe pakuchinja kwetembiricha, zvinogona kubatsira ongororo yedata mune ramangwana, asiwo kuona kuti tembiricha haisi kuzadzisa zvinodiwa nguva ipi. Izvi zvichaita basa guru mukuvandudza kurapwa kwekupisa mune ramangwana.

Maitiro ekushanda

1. Chenesa nzvimbo yekubatira, tarisa kana magetsi, zvishandiso zvekuyeresa uye maswichi akasiyana-siyana ari akajairwa, uye kana mvura iri kuyerera zvakanaka.

2. Vashandi vanofanira kupfeka midziyo yekudzivirira vashandi, zvikasadaro zvichava nengozi.

3, vhura switch yesimba rekudzora, zvichienderana nezvinodiwa zvehunyanzvi zvezvikamu zvemidziyo zvakarongwa zvekuwedzera nekudonha kwekushisa, kuti uwedzere hupenyu hwemidziyo nemidziyo zvisina kukanganiswa.

4, kuteerera tembiricha yekupisa yechoto uye kumhanyisa kwebhandi remambure, inogona kunyatsoongorora mwero wekupisa unodiwa pazvinhu zvakasiyana, kuve nechokwadi chekuoma kwechinhu chebasa uye kutwasuka kwepamusoro uye oxidation layer, uye kuita basa rakachengeteka zvakanyanya.

5. Kuti unyatsoteerera tembiricha yevira rekupisa uye kumhanya kwebhandi repajira, vhura mhepo yekubuda, kuitira kuti workpiece mushure mekudziya ienderane nezvinodiwa zvemhando yepamusoro.

6, mubasa vanofanira kunamatira padanda.

7, kugadzirisa mudziyo wemoto unodiwa, uye kuziva mashandisirwo uye nzira dzekugadzirisa.

8. Pakumisa muchina, tinofanira kutarisa kuti maswichi ese ekudzora ari mu off state, tobva tavhara switch yekuchinjana ye universal.

Kupisa zvakanyanya

Kubva pamuromo wakakombama wezvishongedzo zveroller, zvikamu zvekutakura zvinogona kuonekwa mushure mekudzima microstructure overheating. Asi kuti uone mwero chaiwo wekudzima, unofanira kuona microstructure. Kana muGCr15 steel quenching organization muchionekwa se coarse needle martensite, iri coarse needle martensite, iri coarse needle martensite, iri coarse needle martensite. Chikonzero chekuumbwa kwekudzima, tembiricha yekudziya inogona kunge yakanyanya kana kupisa uye nguva yekubata yakareba zvakanyanya inokonzerwa nehuwandu hwese hwekudzima; zvinogonawo kunge zvichikonzerwa nekurongeka kwekutanga kwebhandi carbide, munzvimbo ine kabhoni shoma pakati pemabhendi maviri kuti igadzire localized martensite tsono gobvu, zvichikonzera localized overheating. Residual austenite mu superheating organization inowedzera, uye dimensional stability inoderera. Nekuda kwekunyanyisa kwe exheating organization, steel crystal is coarse, izvo zvinotungamira mukuderera kwekusimba kwezvikamu, impact resistance inodzikira, uye hupenyu hwe bearing hunodzikirawo. Higher zvakanyanya inogona kutokonzera quenching cracks.

Kudziisa pasi pevhu

Kudzima tembiricha yakaderera kana kutonhora kwakashata kuchaburitsa zvakawanda kupfuura Torrhenite organization yakajairwa mu microstructure, inozivikanwa se underheating organization, iyo inoita kuti kuomarara kudzike, kusakara kwesimbi kunodzikira zvakanyanya, zvichikanganisa hupenyu hwe roller parts bearing.

Kudzima mitswe

Zvikamu zvinotakura maroller mukudzimisa nekutonhodza nekuda kwekumanikidzwa kwemukati zvakaumbwa zvidimbu zvinonzi quenching cracks. Zvikonzero zvekutsemuka kwakadaro ndeizvi: nekuda kwekudzima, tembiricha yekupisa yakanyanya kana kutonhora kunokurumidza, kushushikana kwekupisa uye shanduko yehuwandu hwesimbi mukugadzirwa kwekushushikana kwakakura kupfuura simba rekutsemuka kwesimbi; pamusoro pebasa rezvikanganiso zvepakutanga (senge kuputika kwepamusoro kana kukwenya) kana zvikanganiso zvemukati musimbi (senge slag, zvidimbu zvakakomba zvisiri zvesimbi, mavara machena, shrinkage residue, nezvimwewo) mukudzima kwekuumbwa kwekumanikidzwa; decarburization yakanyanya pamusoro uye Carbide separation; zvikamu zvinodzimwa mushure mekudzima zvidimbu zvisina kukwana kana kuti zvisati zvasvika nguva; kushushikana kwechando kunokonzerwa nemaitiro apfuura kwakakura zvakanyanya, forging folding, deep turning cuts, oil grooves sharp edges nezvimwewo. Muchidimbu, chikonzero chekudzima zvidimbu chingave chimwe kana kupfuura chezvinhu zvataurwa pamusoro apa, kuvapo kwekumanikidzwa kwemukati ndicho chikonzero chikuru chekuumbwa kwezvidimbu zvinodzima. Kudzima zvidimbu kwakadzika uye kwakatetepa, nekutsemuka kwakatwasuka uye kusina ruvara rweoxidized pamusoro wakatsemuka. Kazhinji kacho rukawo rwakati sandara kana kuti rukawo rwakaita serin'i pakora yeberea; chimiro chiri pabhora resimbi reberea chakaita seS, chakaita seT kana kuti chakaita serin'i. Hunhu hwekudzima rukawo hakusi chinhu chekubvisa kabhoni kumativi ese erukawo, chinoonekwa zvakajeka kubva pakuumba rukawo uye rukawo rwezvinhu.

Kugadziriswa kwekurapa kupisa

Zvikamu zveNACHI zvinotakura zvinogadzirwa nekupisa, pane kushushikana kwekupisa uye kushushikana kwesangano, kushushikana uku kwemukati kunogona kukwidziridzwa pamusoro peumwe neumwe kana kuderedzwa zvishoma, kwakaoma uye kunoshanduka-shanduka, nekuti kunogona kuchinjwa nekupisa tembiricha, kupisa kwekupisa, kutonhora kwemodhi, kutonhora kwemodhi, chimiro nehukuru hwezvikamu, saka kupisa kwekupisa hakudzivisiki. Ziva uye ziva mutemo wemutemo unogona kuita kuti kukanganiswa kwezvikamu zvinotakura (senge oval yekora, saizi yakakwira, nezvimwewo) zviiswe munzvimbo inodzorwa, inobatsira kugadzirwa. Ehe, mukupisa kwekugadzirisa kurongeka kwemakanika kuchaitawo kuti zvikamu zvidzorerwe, asi kukanganiswa uku kunogona kushandiswa kuvandudza mashandiro ekuderedza nekudzivirira.

Kubvisa kabhoni pamusoro

Zvishongedzo zveroller zvinotakura zvikamu panguva yekupisa, kana zvikapiswa mumhepo inooxidizing, pamusoro pacho pachaoxidized kuitira kuti chikamu checarbon mass chezvikamu chideredzwe, zvichikonzera kubviswa kwecarburization pamusoro. Kudzika kwechikamu chinooxidization pamusoro kupfuura kugadziriswa kwekupedzisira kwehuwandu hwekuchengetedza kuchaita kuti zvikamu zviparadzwe. Kuongororwa kwehudzamu hwechikamu chinooxidization pamusoro pacho mukuongorora metallographic yemethod iripo yemethod uye microhardness method. Kupararira kwe microhardness kwechikamu chepamusoro kunobva pane nzira yekuyera, uye kunogona kushandiswa senzira yekugadza arbitration.

Nzvimbo yakapfava

Nekuda kwekusakwana kwekudziya, kutonhora kusina kunaka, uye kushanda kwekudzima kunokonzerwa nekuomarara kwenzvimbo dze roller bearing hazvina kukwana, inozivikanwa sekudzimisa nzvimbo yakapfava. Zvakafanana nekubviswa kwecarburization pamusoro kunogona kukonzera kudzikira kukuru kwekudzivirira kupfeka kwepamusoro uye simba rekuneta.

Nguva yekutumira: Zvita-05-2023