Tsananguro yeChigadzirwa

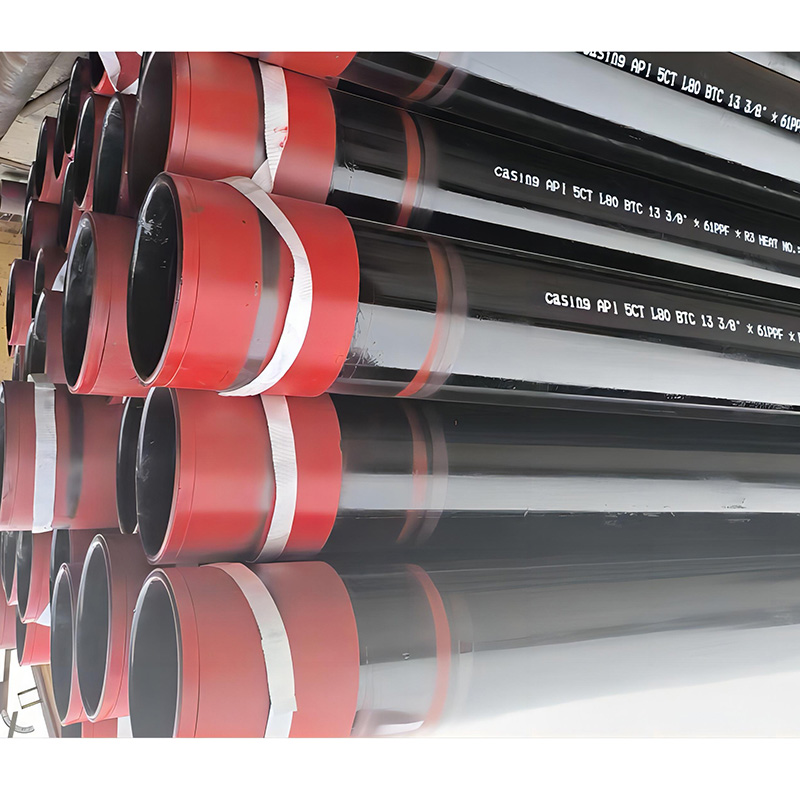

Makesi nemachubhu anoshandiswa zvakanyanya mumafuta negasi, Makesi nemachubhu zvinhu zvakakosha muindasitiri yemafuta negasi zvinoshandiswa pakubvisa nekutakura mahydrocarbon (mafuta negasi rechisikigo) kubva mumatangi epasi pevhu kuenda pamusoro. Anoita basa rakakosha mukuona kuchengetedzeka, kuvimbika, uye kushanda zvakanaka kwemabasa ekuchera nekugadzira.

Tubing imhando yemapaipi anoshandiswa kutamisa mafuta asina kucheneswa negasi rechisikigo kubva muchikamu chemafuta kana chikamu chegasi kuenda pasi mushure mekunge kuchera kwapera. Tubing can inobvumira kumanikidzwa kunogadzirwa panguva yekuburitsa. Tubing inogadzirwa nenzira imwecheteyo nekavha, asi maitiro anonzi "upsetting" anodiwawo kuti pombi yetubing ikodze.

Chivharo chinoshandiswa kuchengetedza maburi akacherwa muvhu kuti awane oiri. Chinoshandiswa zvakafanana nepombi yekuboorera, mapaipi ekuisa mafuta anobvumirawo kumanikidzwa kwe axial tension, saka simbi yakasimba yepamusoro-soro inodiwa. Mabhokisi eOCTG mapaipi makuru ane dhayamita yakasungirirwa mugomba.

Magadzirirwo

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

Rondedzero yeISO/API Steel Casing

| Zviratidzoa | Kunze dhayamita D mm | Zita rekuti mutsara uremub, c Mhedzisiro neMitemo kg/m | Rusvingo ukobvu t mm | Rudzi rwekupedzisira-kupera | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Rudzi 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS PSB PSLB — — | PS PSB PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB PLB | — — — — PLB |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS PSLB PSLBE — — — — | PS PSLB PLB PLB PLB — — | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — — PLBE PLB PLB PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS PSLBE PSLBE | PS PSLB PLB PLB PLB | — — PLBE PLBE PLBE — — — — — — — | PLBE PLBE PLBE | PLBE PLBE PLBE P P P P P P P | PLBE PLBE PLBE | — — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | PSLB PSLBE — | PSLB PLB PLB — | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS PSLBE PSLBE — — — — — — — — — | — PS PLB PLB PLB PLB — — — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P | — — — PLBE PLBE PLBE PLBE PLBE — — — — — | — — — — — — PLBE PLBE — — — — — |

| Ona zvinyorwa zviri kumagumo kwetafura. | ||||||||||||

| Zviratidzoa | Kunze dhayamita D mm | Zita rekuti mutsara uremub, c Mhedzisiro neMitemo kg/m | Rusvingo ukobvu t mm | Rudzi rwekupedzisira-kupera | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Rudzi 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | PSLBE | PSLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB P P | PLBE PLBE PLBE PLB PLB PLB | PLBE PLB PLB PLB |

| 7-3/4 | 46.10 | 19,685 | 6,860 | 1,511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — PSLBE PSLBE — — — | PS PS PSLB PSLB PLB — — | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — — PLBE PLBE PLBE | — — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — PSLB PSLBE — — — — — — — — | — PSLB PSLB PLB PLB — — — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB P P P P | — — — PLBE PLBE PLBE PLB — — — — | — — — — PLBE PLBE PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | PSB PSBE PSBE | PSB PSB PSB PSB | PSBE PSBE | PSBE PSBE | PSBE PSBE PSBE PSB P P P | PSBE PSBE PSBE PSB | PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | PSB PSB PSB — — | PSB PSB PSB — — | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — PSB PSB PSB — | — PSB PSB PSB — | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — — PSB |

| Ona zvinyorwa zviri kumagumo kwetafura. | ||||||||||||

| Zviratidzoa | Kunze dhayamita D mm | Zita rekuti mutsara uremub, c Mhedzisiro neMitemo kg/m | Rusvingo ukobvu t mm | Rudzi rwekupedzisira-kupera | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Rudzi 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | PSB PSB P | PSB PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47,308 | 13,021 | 1,105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | PSL — — | PSLB PSLB PSLB | PSLB PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Mugumo usina kuzara, S = Tambo pfupi yakatenderera, L = Tambo refu yakatenderera, B = Tambo yesimbi, E = Mutsetse wakanyanyisa. | ||||||||||||

| ♦ Mazita ekunyorera ndeeruzivo nerubatsiro pakuodha. ♦ Masvosve emutsetse, akarukwa uye akabatana (chikamu 2) anoratidzwa chete seruzivo. ♦ Kuwanda kwesimbi dzemartensitic chromium (L80 types 9Cr and 13Cr) kwakasiyana nesimbi dzekabhoni. Saka huremu hwakaratidzwa hahuna kururama kune simbi dzemartensitic chromium. Chinhu chinogadzirisa huremu che0,989 chinogona kushandiswa. | ||||||||||||

| Zviratidzo | Dhayamita yekunze D mm | Mutsetse wakajeka uremu kg/m | Ukobvu hwemadziro t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

Rondedzero yeISO/API Steel Tubing

| Zviratidzo | Kunze dhayamita D mm | Mutsetse wezita masasia, b | Rusvingo gobvu- ness t mm | Rudzi rwekupedzisa kwekupedzisirac | |||||||||||

| Kwete- kugumbuka Mhedzisiro neMitemo kg/m | Zvimwe kugumbuka Mhedzisiro neMitemo kg/m | Kubatana. joini kg/m | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Mhedzisiro neMitemo | EU Mhedzisiro neMitemo | IJ | H40 | J55 | L80 | N80 Rudzi 1, Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.900 1.900 1.900 1.900 1.900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI PNUI PU — — | PI PNUI PU — — | — PNUI PU P P | — PNUI PU — — | — PNUI PU P P | — PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN PNU | PN PNU | PN PNU PNU P PU | PN PNU PNU — — | PN PNU PNU P PU | PN PNU PNU P PU | PNU PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | PNU — — | PNU — — | PNU PNU PNU PU | PNU PNU PNU — | PNU PNU PNU PU | PNU PNU PNU PU | PNU PNU PNU — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN PNU PN — — — — | PN PNU PN — — — — | PN PNU PN PNU P P P | PN PNU PN PNU — — — | PN PNU PN PNU P P P | PN PNU PN PNU P P P | — PNU — PNU — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | — 11.00 — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | PNU | PNU | PNU P P P P P P | PNU — — — — — — | PNU P P P P P P | PNU P P P P P P | |||

| P = Mugumo usina kujeka, N = Yakaputirwa isina kugadzikana uye yakabatana, U = Yakaputirwa yekunze uye yakabatana, I = Joinhi rakabatana. | |||||||||||||||

| ♦ Masvosve emutsetse, tambo nekubatanidza (col. 2, 3, 4) zvinoratidzwa chete seruzivo. ♦ Kuwanda kwesimbi dzemartensitic chromium (L80 types 9Cr and 13Cr) kwakasiyana nesimbi dzekabhoni. Saka huremu hwakaratidzwa hahuna kururama kune simbi dzemartensitic chromium. Chinhu chinogadzirisa huremu che0,989 chinogona kushandiswa. ♦ Machubhu asina kukanganiswa anowanikwa nemachira akajairwa kana machira akakosha e bevel. Machubhu ekunze-anokanganisa anowanikwa nemachira akajairwa, akakosha, kana akakosha ekubvisa. | |||||||||||||||

Standard & Giredhi

Kuisa nekuisa machubhu Magiredhi Akajairika:

API 5CT J55,K55,L80, N80,P110, C90, T95, H40

Magumo emapaipi eAPI 5CT casing uye tube:

(STC) Kabhini pfupi yakatenderera yeshinda

(LC) Chivharo chetambo refu chakatenderera

(BC) Chivharo cheshinda chebuttress

(XC)Kasi repamusoro-soro

(NU)Machubhu asingakanganisi

(EU) Machubhu ekunze anoputika

(IJ) Integral joint tube

Chivharo nemachubhu zvinofanirwa kuendeswa zvichienderana nezvinodiwa pamusoro apa maererano nemazinga eAPI5CT / API Standards.

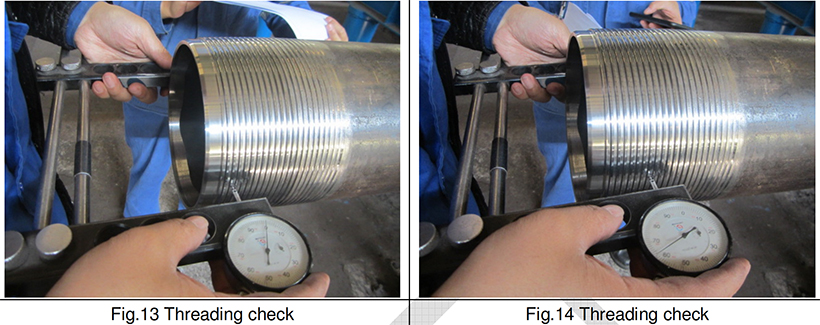

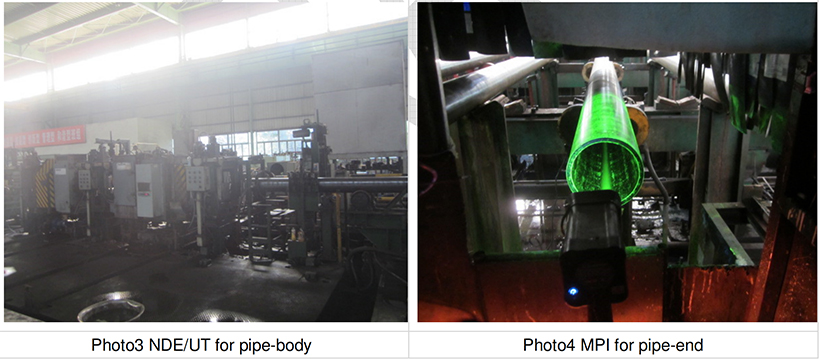

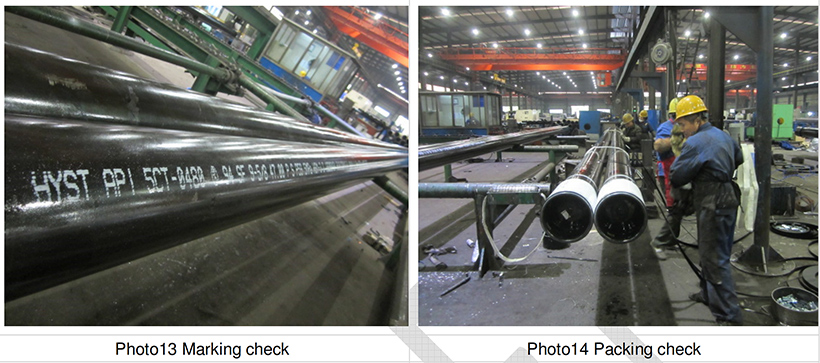

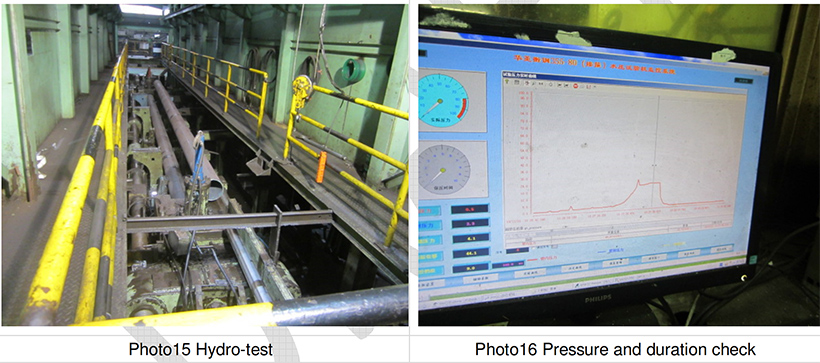

Kudzora Hunhu

Kuongorora Zvinhu Zvisina Kugadzirwa, Kuongorora Makemikari, Kuedza Kwemuchina, Kuongorora Zvinoonekwa, Kuedza Kushushikana, Kutarisa Dimension, Kuedza Kukombama, Kuedza Kutsetseka, Kuedza Kwekukanganisa, Kuedza DWT, Kuedza kweNDT, Kuedza kweHydrostatic, Kuedza Kwekuoma…..

Kumaka, Kupenda usati waendesa.

Kurongedza & Kutumira

Nzira yekurongedza mapaipi esimbi inosanganisira kuchenesa, kuisa mumapoka, kuputira, kusungirira, kusunga, kunyora mazita, kuisa mapaleti (kana zvichidikanwa), kuisa mumidziyo, kuisa mumidziyo, kuisunga, kuifambisa, uye kuiburitsa. Mhando dzakasiyana dzemapaipi esimbi nenzira dzakasiyana dzekurongedza. Maitiro aya akazara anoita kuti mapaipi esimbi atumirwe uye asvike kwaanofanira kuenda ari mumamiriro akanaka, akagadzirira kushandiswa kwawo.

Kushandisa & Kushandiswa

Mapaipi esimbi anoshanda semusana weinjiniya yemazuva ano yeindasitiri neyezvivakwa, achitsigira mashandisirwo akasiyana-siyana anobatsira mukusimudzira nzanga nehupfumi pasi rese.

Mapaipi esimbi nezvinhu zvakagadzirwa neWomic Steel zvinoshandiswa zvakanyanya pakugadzira peturu, gasi, mafuta & mapaipi emvura, pamhenderekedzo yegungwa / pamhenderekedzo yegungwa, mapurojekiti ekuvaka nekuvaka, kugadzira matombo, mapurojekiti ekuvaka Simbi, kuisa mapuranga nemabhiriji, pamwe nemachubhu esimbi akanyatsogadzirwa ekugadzira maroller ekutakura zvinhu, nezvimwewo ...