Tsananguro yeChigadzirwa

Mapaipi esimbi anotenderera, anozivikanwawo semapaipi esimbi anotenderera arc-welded (HSAW), imhando yemapaipi esimbi anozivikanwa nemaitiro awo akasiyana ekugadzira uye hunhu hwemaumbirwo awo. Mapaipi aya anoshandiswa zvakanyanya mumaindasitiri akasiyana-siyana nekuda kwesimba rawo, kugara kwenguva refu, uye kugona kuchinjika. Heino tsananguro yakadzama yemapaipi esimbi anotenderera:

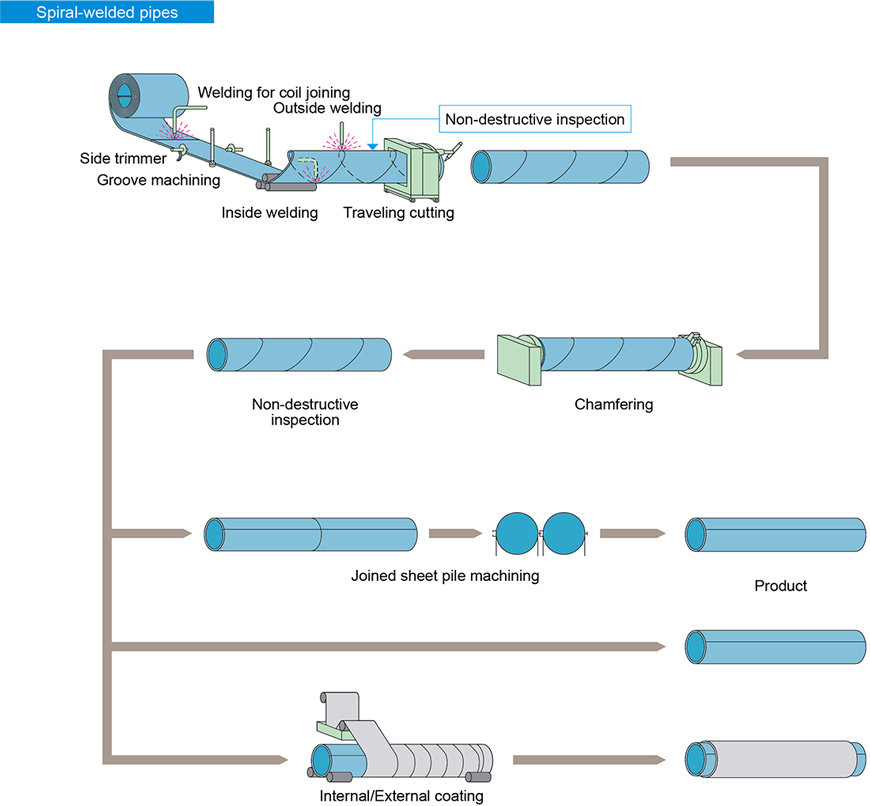

Maitiro Ekugadzira:Mapaipi esimbi anotenderera anogadzirwa nenzira yakasiyana inoshandisa coil yesimbi. Chidimbu chacho chinovhurwa uye chinogadzirwa kuita chimiro che spiral, chobva chabatanidzwa uchishandisa nzira ye submerged arc welding (SAW). Maitiro aya anoguma nemusono unotenderera, wakatenderera pakureba kwepombi.

Dhizaini yeZvivako:Musono wesimbi inotenderera unopa simba rayo, zvichiita kuti ikwanise kutsungirira mitoro yakakwira uye kumanikidzwa. Dhizaini iyi inoita kuti pave nekupararira kwakafanana kwekumanikidzwa uye inowedzera kugona kwepaipi kuramba kukotama nekukanganisika.

Saizi Yehukuru:Mapaipi esimbi anotenderera anouya nedhayamita dzakasiyana-siyana (kusvika 120 Inch) uye ukobvu, zvichibvumira kuchinjika mukushandiswa kwakasiyana-siyana. Anowanzo kuwanikwa mudhayamita dzakakura kana tichienzanisa nedzimwe mhando dzemapaipi.

Mashandisirwo:Mapaipi esimbi anotenderera anoshandiswa mumaindasitiri akasiyana-siyana akadai semafuta negesi, mvura, kuvaka, kurima, uye kuvandudza zvivakwa. Akakodzera kushandiswa pamusoro pevhu uye pasi pevhu.

Kuramba Kuora:Kuti zvinhu zvirambe zvakamira kwenguva refu, mapaipi esimbi anotenderera anowanzo shandiswa pakurapa ngura. Izvi zvinogona kusanganisira machira emukati nekunze, akadai se epoxy, polyethylene, uye zinc, anodzivirira mapaipi kubva kuzvinhu zvakatipoteredza nezvinhu zvinoparadza.

Zvakanakira:Mapaipi esimbi anotenderera ane zvakanakira zvakawanda, zvinosanganisira kugona kutakura zvinhu zvakawanda, kushandisa mari shoma pamapaipi ane dhayamita hombe, nyore kuisa, uye kuramba kuchinja. Magadzirirwo awo anobatsirawo mukubvisa mvura zvakanaka.

KurebaVSKutenderera:Mapaipi esimbi anotenderera anogona kusiyaniswa nemapaipi akasungirirwa kwenguva refu kuburikidza nemaitiro avo ekugadzira. Kunyange zvazvo mapaipi enguva refu achiumbwa uye akasungirirwa pamwe chete nehurefu hwepaipi, mapaipi anotenderera ane musono wakakombama wakagadzirwa panguva yekugadzira.

Kudzora Hunhu:Maitiro ekugadzira nekudzora mhando akakosha mukugadzira mapaipi esimbi anotenderera akavimbika. Zvinodiwa pakushongedza, geometry yemapaipi, uye nzira dzekuyedza zvinotariswa nekungwarira kuitira kuve nechokwadi chekuti zvinotevedzera mitemo nezvinodiwa muindasitiri.

Mitemo neMagadzirirwo:Mapaipi esimbi anotenderera anogadzirwa zvichienderana nemitemo yepasi rose uye yeindasitiri yakaita seAPI 5L, ASTM, EN, nedzimwe. Mitemo iyi inotsanangura hunhu hwezvinhu, nzira dzekugadzira, uye zvinodiwa pakuedza.

Muchidimbu, mapaipi esimbi anotenderera imhinduro inoshanda zvakasiyana-siyana uye inogara kwenguva refu kumaindasitiri akasiyana-siyana. Maitiro avo ekugadzira akasiyana, simba ravo, uye kuwanikwa kwavo muhukuru hwakasiyana zvinobatsira mukushandiswa kwavo kwakapararira muzvivakwa, kutakura, simba, kuvaka chiteshi chengarava nezvimwe. Kusarudzwa kwakakodzera, kudzora mhando, uye matanho ekudzivirira ngura zvinoita basa rakakosha mukuona kuti mapaipi esimbi anotenderera anoshanda kwenguva refu.

Magadzirirwo

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Giredhi C250, Giredhi C350, Giredhi C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

| Dhayamita (mm) | Ukobvu hwemadziro (mm) | |||||||||||||||||||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

| 219.1 | ● | ● | ● | ● | ||||||||||||||||

| 273 | ● | ● | ● | ● | ● | |||||||||||||||

| 323.9 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 325 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 355.6 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 377 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 406.4 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 426 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 457 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 478 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 508 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 529 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 630 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 711 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 720 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 813 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 920 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1420 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1620 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 1820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2500 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2540 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 3000 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

Kushivirira kwedhayamita yekunze uye ukobvu hwemadziro

| Zvakajairika | Kushivirira kweMuviri wePaipi | Kushivirira kweMugumo wePaipi | Kushivirira Ukobvu hweMadziro | |||

| Dhayamita yekunze | Kushivirira | Dhayamita yekunze | Kushivirira | |||

| GB/T3091 | OD≤48.3mm | ≤±0.5 | OD≤48.3mm | - | ≤±10% | |

| 48.3 | ≤±1.0% | 48.3 | - | |||

| 273.1 | ≤±0.75% | 273.1 | -0.8~+2.4 | |||

| OD>508mm | ≤±1.0% | OD>508mm | -0.8~+3.2 | |||

| GB/T9711.1 | OD≤48.3mm | -0.79~+0.41 | - | - | OD≤73 | -12.5%~+20% |

| 60.3 | ≤±0.75% | OD≤273.1mm | -0.4~+1.59 | 88.9≤OD≤457 | -12.5%~+15% | |

| 508 | ≤±1.0% | OD≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% | |

| OD>941mm | ≤±1.0% | - | - | - | - | |

| GB/T9711.2 | 60 | ±0.75%D~±3mm | 60 | ±0.5%D~±1.6mm | 4mm | ±12.5%T~±15.0%T |

| 610 | ±0.5%D~±4mm | 610 | ±0.5%D~±1.6mm | Huremu ≥25mm | -3.00mm~+3.75mm | |

| OD>1430mm | - | OD>1430mm | - | - | -10.0%~+17.5% | |

| SY/T5037 | OD<508mm | ≤±0.75% | OD<508mm | ≤±0.75% | OD<508mm | ≤±12.5% |

| OD≥508mm | ≤±1.00% | OD≥508mm | ≤±0.50% | OD≥508mm | ≤±10.0% | |

| API 5L PSL1/PSL2 | OD <60.3 | -0.8mm~+0.4mm | OD≤168.3 | -0.4mm~+1.6mm | Uzito≤5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0.75% | 168.3 | ≤±1.6mm | 5.0 | ≤±0.1T | |

| 168.3 | ≤±0.75% | 610 | ≤±1.6mm | T≥15.0 | ≤±1.5 | |

| 610 | ≤±4.0mm | OD>1422 | - | - | - | |

| OD>1422 | - | - | - | - | - | |

| API 5CT | OD<114.3 | ≤±0.79mm | OD<114.3 | ≤±0.79mm | ≤-12.5% | |

| OD≥114.3 | -0.5%~1.0% | OD≥114.3 | -0.5%~1.0% | ≤-12.5% | ||

| ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| DN mm | NB Inchi | OD mm | SCH40S mm | SCH5S mm | SCH10S mm | SCH10 mm | SCH20 mm | SCH40 mm | SCH60 mm | XS/80S mm | SCH80 mm | SCH100 mm | SCH120 mm | SCH140 mm | SCH160 mm | SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12” | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14” | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16” | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24” | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| DN 1000mm zvichikwira Dhayamita ukobvu hwemadziro epombi 25mm | ||||||||||||||||

Standard & Giredhi

| Zvakajairika | Magiredhi eSimbi |

| API 5L: Tsanangudzo yeLine Pipe | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: Tsananguro Yakajairika yeMapombi eSimbi Akasungirirwa uye Asina Musono | GR.1, GR.2, GR.3 |

| EN 10219-1: Zvikamu zveMakomba Zvakaumbwa Zvakasungirirwa Zvakatonhora zveSimbi Dzisina Kugadzirwa uye Dzisina Kugadzirwa | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: Zvikamu zveMakomba Zvakapedzwa Zvakapiswa zveSimbi Dzisina Kugadzirwa uye Dzisina Kugadzirwa | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: Pombi, Simbi, Dema uye Yakanyikwa Inopisa, Yakaputirwa neZinc, Yakasungirirwa uye Isina Musono | GR.A, GR.B |

| EN 10217: Machubhu eSimbi Akasungirirwa Ekushandisa Pakumanikidza | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: Mapaipi eSimbi Akasungirirwa uye Machubhu | St37.0, St44.0, St52.0 |

| AS/NZS 1163: Mwero wekuAustralia/New Zealand wezvikamu zvesimbi yekuvaka zvakagadzirwa nechando | Giredhi C250 , Giredhi C350 , Giredhi C450 |

| GB/T 9711: Maindasitiri ePetroleum neGasi reChisikigo - Mapaipi eSimbi eMapaipi | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| AWWA C200: Pombi yeSimbi yeMvura ine Mainches matanhatu (150 mm) uye Yakakura | Simbi yeKabhoni |

Maitiro Ekugadzira

Kudzora Hunhu

● Kuongorora Zvinhu Zvisina Kugadzirwa

● Kuongorora Makemikoro

● Kuedzwa kweMichina

● Kuongorora Zvinoonekwa

● Kuongorora miganhu

● Kuedza Kukombama

● Kuedza Kukanganisa

● Kuedzwa kweKuora kweIntergranular

● Kuongorora Kusingakuvadzi (UT, MT, PT)

● Kufanirwa Kwenzira Yekushongedza

● Kuongorora Zvimiro Zvidiki

● Kuedza Kupisa uye Kutsvedza

● Kuedza Kuoma

● Kuongororwa kweDhivha

● Kuedzwa kweMetallography

● Kuongororwa Kwengura

● Kuedzwa kweEddy Current

● Kuongorora Kupenda Nekuputira

● Ongororo yeMagwaro

Kushandisa & Kushandiswa

Mapaipi esimbi anotenderera anogona kushandiswa zvakasiyana-siyana uye anoshandiswa zvakanyanya mumaindasitiri akasiyana-siyana nekuda kwehunhu hwawo hwakasiyana uye zvakanakira. Anoumbwa nekusanganisa simbi pamwe chete nesimbi kuti pave nepaipi ine musono unotenderera unoenderera mberi. Heano mamwe mashandisirwo akajairika emapaipi esimbi anotenderera:

● Kutakurwa Kwemvura: Mapaipi aya anonyatsofambisa mvura, mafuta, negesi padaro refu mumapaipi nekuda kwekuvakwa kwawo kusina musono uye simba rakawanda.

● Oiri neGasi: Zvakakosha kumaindasitiri emafuta negasi, zvinotakura mafuta asina kucheneswa, gasi rechisikigo, nezvinhu zvakanatswa, zvichibatsira pakutsvaga nekuparadzira.

● Kuunganidza: Mirwi yenheyo mumapurojekiti ekuvaka inotsigira mitoro inorema muzvivakwa zvakaita sezvivakwa nemabhiriji.

● Kushandiswa kwechivako: Zvichishandiswa mukuvaka mafuremu, makoramu, uye zvinotsigira, kugara kwenguva refu kwazvo kunoita kuti chivako chigadzikane.

● Makomba emvura neMadhairekita: Zvinoshandiswa muzvirongwa zvemvura, zvinodzivirira ngura uye mukati mazvo zvakatsetseka zvinodzivirira kuvharika uye zvinoita kuti mvura ifambe zvakanaka.

● Kugadzira Machubhu Emuchina: Mukugadzira nekurima, mapaipi aya anopa mhinduro dzakasimba uye dzinodhura zvishoma pazvikamu.

● Mugungwa neMugungwa: Panzvimbo dzakaoma, dzinoshandiswa mumapaipi emvura, mapuratifomu egungwa, uye kugadzirwa kwejetty.

● Kuchera: Vanotakura zvinhu netsvina mumabasa ekuchera akaomarara nekuda kwekuvakwa kwavo kwakasimba.

● Kuwanikwa Kwemvura: Yakanakira mapaipi makuru ari muhurongwa hwemvura, ichitakura mvura yakawanda zvinobudirira.

● Masisitimu eGeothermal: Anoshandiswa mumapurojekiti esimba regeothermal, anobata kutamiswa kwemvura inodzivirira kupisa pakati pematangi emvura nemagetsi.

Kushanduka-shanduka kwemapaipi esimbi anotenderera, pamwe chete nesimba rawo, kugara kwenguva refu, uye kuchinjika, zvinoita kuti ave chinhu chakakosha mumaindasitiri akasiyana-siyana uye mashandisirwo awo.

Kurongedza & Kutumira

Kurongedza:

Maitiro ekurongedza mapaipi esimbi anotenderera anosanganisira matanho akati wandei akakosha ekuona kuti mapaipi akachengetedzwa zvakakwana panguva yekufambisa nekuchengetedza:

● Kubatanidza Mapaipi: Mapaipi esimbi anotenderera anowanzobatanidzwa pamwe chete achishandisa tambo, mabhandi esimbi, kana dzimwe nzira dzakachengeteka dzekusunga. Kubatanidza kunodzivirira mapaipi ega ega kuti asafambe kana kufamba mukati mepakeji.

● Dziviriro yeMagumo ePaipi: Zvivharo zvepurasitiki kana zvivharo zvekudzivirira zvinoiswa pamativi ese emapaipi kudzivirira kukuvara kwemagumo epaipi nepamusoro pemukati.

● Kudzivirira Kupinda Mvura: Mapaipi anoputirwa nezvinhu zvisingapindi mvura, zvakaita semapurasitiki kana kuputira, kuti adzivirirwe kubva muhunyoro panguva yekufambisa, kunyanya mukutakura zvinhu kunze kana mugungwa.

● Kuisa mapedhi: Zvimwe zvinhu zvekuisa mapedhi, zvakaita semafuro kana zvinhu zvekuisa mapedhi, zvinogona kuwedzerwa pakati pemapaipi kana panzvimbo dzisina kugadzikana kuti zvidzivirire kuvhunduka nekudedera.

● Kunyora: Boka rega rega rine ruzivo rwakakosha, kusanganisira zvinodiwa papombi, saizi, huwandu, uye kwainofanira kuendeswa. Izvi zvinobatsira pakuzivikanwa uye kubata zviri nyore.

Kutumira:

● Kutumira mapaipi esimbi anotenderera kunoda kuronga nokungwarira kuti pave nechokwadi chekuti kutakurwa kwakachengeteka uye kunoshanda:

● Nzira Yekufambisa: Sarudzo yenzira yekufambisa (mugwagwa, njanji, gungwa, kana mhepo) inoenderana nezvinhu zvakaita sedaro, kukurumidza, uye kusvika kwaunoda kuenda.

● Kuisa mumidziyo: Mapaipi anogona kuiswa mumidziyo yekutakura zvinhu yakajairika kana mumidziyo yakagadzirwa zvakanaka. Kuisa mumidziyo kunodzivirira mapaipi kubva kuzvinhu zvekunze uye kunopa nharaunda inodzorwa.

● Kuchengetedza: Mapaipi anosungirirwa mumidziyo achishandisa nzira dzakakodzera dzekusunga, dzakadai sekusimbisa, kuvharira, uye kurovera. Izvi zvinodzivirira kufamba uye zvinoderedza njodzi yekukuvadzwa panguva yekufambisa.

● Magwaro: Magwaro akarurama, anosanganisira ma invoice, runyorwa rwezvinhu zvinoiswa muzvitoro, uye manifest ekutumira zvinhu, akagadzirirwa kubvisirwa kwemitengo yemutero nekutevera.

● Inishuwarenzi: Inishuwarenzi yekutakura zvinhu inowanzo wanikwa kuti ivhare kurasikirwa kana kukuvara kunogona kuitika panguva yekufambisa.

● Kutarisa: Mukati menguva yese yekutumira, mapaipi anogona kuteverwa uchishandisa GPS uye masisitimu ekutevera kuti ave nechokwadi chekuti ari munzira chaiyo uye panguva chaiyo.

● Kubviswa Kwemari Munyika: Magwaro akakodzera anopiwa kuti zvive nyore kubvisa mari munyika pachiteshi chengarava kana pamuganhu.

Mhedziso:

Kurongedza nekutumirwa kwemapombi esimbi anotenderera kwakakodzera kwakakosha kuchengetedza hunhu hwemapaipi panguva yekufambisa. Kutevedzera nzira dzakanakisisa dzeindasitiri kunoita kuti mapaipi asvike kwaanoenda ari mumamiriro akanaka, akagadzirira kuiswa kana kugadziriswa zvakare.